What is cellular glass insulation?

Cellular glass insulation is a thermal insulation category that has recycled glass and sand as base materials, supplemented by mineral substances and other natural materials.

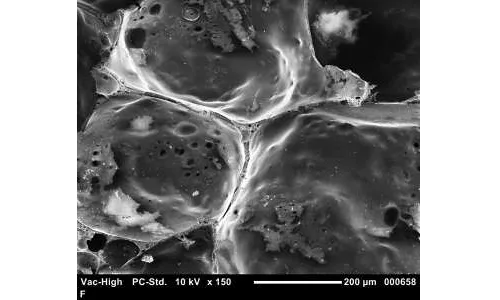

It is an inorganic insulation material that is composed of millions of completely sealed glass cells.

This closed cell structure captures the produced gas in the cells, giving the insulating property to the material and ensuring a stable thermal conductivity for many years. No water molecules can diffuse in the glass cells and internal condensation is impossible. The result is a vapour-tight, incombustible material with an extraordinary compressive strength.

Owens Corning FOAMGLAS® is the world’s market leader

in cellular glass insulation.

- The average recycled content for FOAMGLAS® products is 50%*.

- FOAMGLAS ® slabs are VOC free and contain no volatile substances.

- FOAMGLAS ® insulation offers an exceptional combination of protective properties such as incombustibility, superior compressive strength, 100% water and moisture resistance.

- Based on third-party testing, our insulation material has proven not to deteriorate over time. Thermal performance and load-bearing capacities remain constant throughout the lifetime of the building.

- It protects people, assets and the environment.

- It is available in a wide range of shapes and sizes to satisfy various building requirements and industrial specifications.

* Weighted average based on total mass of final products in the market. Calculation based on ISO 22095 rolling average percentage method.

The inorganic safety insulation

As FOAMGLAS® cellular glass insulation is an inorganic material, it will not burn or support combustion. Flame spread and smoke development are prevented and it does not cause any dangerous droplets, making it a truly firesafe construction material. Additionally, because of the 100% inorganic nature of cellular glass, it does not interact with oxidising liquids, minimising explosion risks associated with the oxidising of organic materials.

Properties

of FOAMGLAS® insulation

It is the combination of all its protective properties that makes cellular glass insulation so unique. No other thermal insulation can offer all of these properties in one product. The importance of each is related to the specificities of the respective Industry and Building projects.

Impermeable

FOAMGLAS® insulation is waterproof because it consists of glass. Advantage: does not absorb any moisture and does not swell.

> Read more about our 100% water resistance

Vapour-tight

FOAMGLAS® insulation is vapour-tight because it is made of hermetically sealed glass cells. Advantage: no vapour can pass through and the FOAMGLAS layer acts as a vapour barrier, resulting in a constant thermal insulation value over decades with no risk of condensation or corrosion.

> Read more about our vapour resistance

Non-combustible

FOAMGLAS® insulation is incombustible due to its glass cell structure. Fire behaviour: classification according to EN 13501: A1. Advantage: storage and processing are not hazardous; no propagation of flames in the event of fire (chimney effect) in a ventilation space.

> Read more about our incombustibility

High compressive strength

FOAMGLAS® insulation has high compressive strength even with long-term loads due to its cell geometry without deformation. Advantage: use of load-bearing thermal insulation without any risks.

> Read more about our load baring capacities

Thermal performance

FOAMGLAS® insulation has a service temperature that ranges between -265 °C and 430 °C. Advantage: long-term thermal performance with constant insulating efficiency throughout the full lifetime of the building or industrial installation.

> Read more about our thermal performance

Dimensionally stable

FOAMGLAS® insulation is dimensionally stable because glass does not shrink or swell. The advantage: no warping, buckling or creep. In addition, the low coefficient of expansion, almost equal to that of steel or concrete, results in a longer lifetime for the waterproofing membranes.

Resistant to acid

FOAMGLAS® insulation is resistant to organic solvents and acids because it is made of pure glass. Advantage: no destruction of the insulation by aggressive mediums and atmospheres.

Durable

FOAMGLAS® insulation is free of environmentally damaging flame retardants, propellants and eco-toxic components. Advantage: after generations of use as thermal insulation, FOAMGLAS® slabs can be recycled as filler in landscaping or thermally insulating granulate for meaningful ecological recycling through re-uses.

Resistant to radon gas

FOAMGLAS® insulation prevents the penetration of radon because it consists of hermetically sealed glass cells. Advantage: 100% safe radon barrier and thermal insulation in one layer.

Pest-proof

FOAMGLAS® insulation is unable to rot and is pest-proof because it is inorganic. Advantage: insulation without risk, especially in the base area and the soil. There is no basis for nesting, breeding or seed germination.

Durable and sustainable

in its core

Consisting of pure glass, FOAMGLAS® cellular glass insulation is free of environmentally damaging flame retardants and propellants and has no relevant eco-toxic components.

Third party testing (FIW Institute – Munich) has proven FOAMGLAS® insulation to be a truly durable insulation material. The insulation does not deteriorate over time, maintaining its thermal resistance and compressive strength throughout the lifetime of the building, industrial installation or storage tank.

During renovation work of the building, or when renovating the waterproofing membrane, our insulation can stay in place and does not need to be replaced. In case of stricter regulations regarding the thermal performance of a building in the future, you can easily add another layer of FOAMGLAS® insulation on top of the existing one, improving the U value of the building.

After generations of use as thermal insulation, FOAMGLAS® insulation can be recycled when the building is dismantled. It can then be reused as filler in landscaping or thermally insulating granulate in road construction. A perfect example of meaningful ecological recycling through re-use.

The production

of FOAMGLAS® insulation

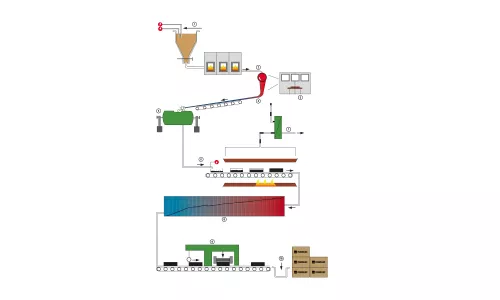

The average recycled content for FOAMGLAS® products is 50%*. The mix of raw materials, in combination with adjustments during the manufacturing process, determine the unique combination of FOAMGLAS® properties.

1. First, glass is obtained from a mix of recycled glass, sand, dolomite, lime and iron oxide with precisely defined properties.

2. The glass is then ground and mixed with a small amount of carbon in the ball mill.

3. The powder is put in high-grade steel moulds, which then pass through a furnace where the glass foam powder is expanded.

4. A material structure with thin glass air cells emerges. These are retained in a controlled cooling process. Due to the closed cell structure, millions of tiny hermetically sealed glass cells give the material extraordinary compressive strength, excellent insulation values and waterproofing properties.

5. After cooling, the produced material is cut to size, packed and stacked on pallets, ready for our warehouse or delivery to the jobsite.

* Weighted average based on total mass of final products put on the market. Calculation based on ISO 22095 rolling average percentage method.

Our production facility worldwide

Owens Corning FOAMGLAS® has 4 production plants worldwide.