FOAMGLAS® insulation for consistent thermal performance

Thermal insulation should offer reliable and consistent performance, even in demanding environments. However, many insulation types lose performance over time, impacting on the efficiency and operating costs of the building or industrial application in which the insulation is installed.

Long term thermal performance of insulation

Over time it is possible that building insulation materials lose their thermal performance. The insulation may deform under load, and not retain its shape. It may absorb moisture and vapour.

The structure of insulation materials also affects their long term performance. The thermally efficient gas within the cells of rigid polyisocyanurate (PIR) foam insulation, gradually leaks out over time; therefore consistent thermal performance cannot be guaranteed.

Any of these issues impact on the proper functioning of the insulation system; the most common being the accumulation of moisture leading to inconsistent thermal performance. All this leads to the risk of uncomfortable and unhealthy indoor climates, higher energy use and energy bills. In the longer term there is the potential expense and inconvenience of repairing or replacing the insulation.

Thermal performance of insulation in industrial applications

Some industrial processes require strict temperature control, and therefore rely on thermal insulation performing reliably and consistently. Liquid in storage tanks, for example, must not freeze or solidify. In extreme cases, poor temperature control in sensitive applications can cause excessive evaporation and result in dangerous pressure levels in the storage tank.

Testing the long term performance of FOAMGLAS® insulation

A 2017 study by the Forschungsinstitut für Wärmeschutz (FIW), a Munich-based research facility for insulation, showed that FOAMGLAS® insulation retains its thermal conductivity (lambda value), after almost 50 years installed upon a flat roof.

FOAMGLAS® offers the best performing cellular glass insulation. Our T3+ product has a thermal conductivity of 0.036 W/mK, which is typically equivalent to the performance offered by mineral wool insulation.

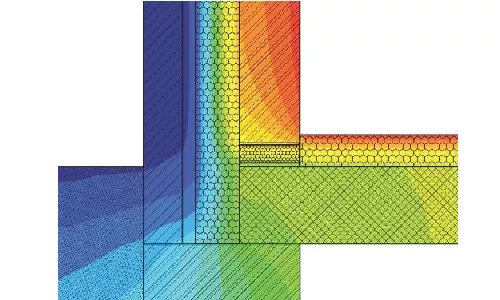

Cellular glass insulation is made up of millions of glass cells. Each glass cell is separate from another, it is hermetically sealed, making it a water proof and vapour tight insulation. The cells retain their shape, and can support high compressive loads, the insulation never deforms. Loss of thermal performance is eliminated; FOAMGLAS® is specified in building and industrial applications with complete confidence.

There is a FOAMGLAS® insulation product for all applications around the entire building envelope, from basements to roofs. It is specified in a diverse range of applications, including schools, hospitals and rooftop car parking decks and in demanding environments such swimming pools, laundries and professional kitchens. In all applications the thermal efficiency; and hence energy efficiency, remain consistent for the life of the building.

Using FOAMGLAS® insulation for efficient industrial processes

In the industrial sector, FOAMGLAS® insulation is the material of choice for cold and cryogenic applications in the petrochemical and oil and gas sectors. The long term thermal efficiency of FOAMGLAS® insulation, including in extreme conditions, results in a short payback time and ensures that installations run efficiently through better process control.

What temperature range can FOAMGLAS®insulation be used in?

FOAMGLAS® insulation is proven to retain its level of thermal performance for many years. During building maintenance or renovation work, existing FOAMGLAS® insulation can remain in place.

If additional thermal performance is required, another layer of FOAMGLAS® insulation is easily overlaid upon the existing insulation. For industrial applications, FOAMGLAS®insulation works within a very wide temperature range from -269°C to +482°C.