Protect what matters most

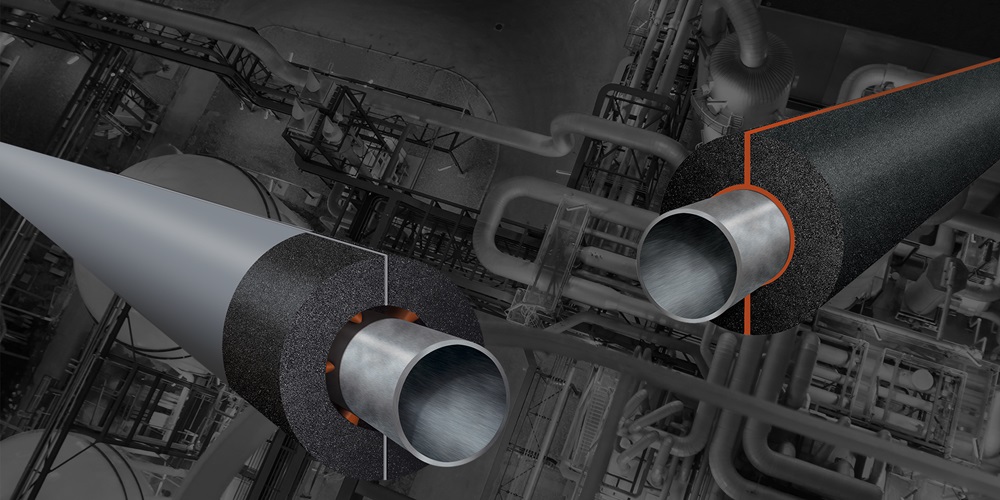

Owens Corning FOAMGLAS® thermal insulation made of cellular glass

FOAMGLAS® cellular glass insulation is a light weight, rigid and durable insulation material, composed of millions of completely sealed glass cells. It offers an exceptional combination of properties such as incombustibility, superior compressive strength, guaranteed water- and vapour tightness and long lasting thermal insulation performance.

FOAMGLAS® insulation is your partner in any demanding situation where preventing leakage or condensation is critical. We offer high-performance insulation solutions for waterproof buildings, industrial installations, marine and HVAC applications. Our solutions also insulate loadbearing heavy duty surfaces such as flat roofs, underground, and oil & gas tank bases. Best-in-class technical service, from the design and critical detailing to the installation, is included in order to give you peace of mind.