What are the benefits of modular construction?

For LNG insulation projects.

Modular construction has been a fairly common practice for many types of projects across the world for more than a century. However, modular construction for LNG projects is a more recent event but modularization when used for large scale LNG projects bring a lot of benefits to the table.

Modularization

Modular construction has been a fairly common practice for many types of projects across the world. However, modular construction for LNG projects is a more recent trend.

Modular construction is the building of pre-fabricated modules at sites other than the actual project site. Traditional construction of a LNG project would consist of “stick build” at the main construction site. A modular approach helps decrease the workload at the actual project site. As a result, modular construction can often be a viable, safe, cost-effective solution for many projects – including those in the LNG industry.

While it is not the solution for every project, modular construction has been shown to be a beneficial solution in many cases. This is primarily due to projects having tighter schedules and budgets. Consequently, modular construction is often a viable solution for projects to be carried out successfully and efficiently.

THe pros of modularization

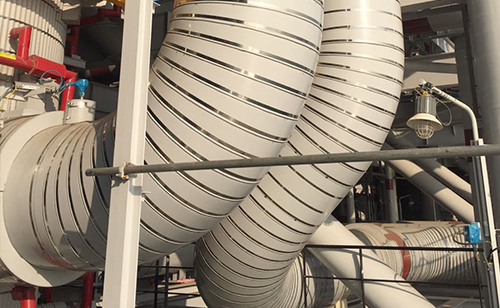

The modular construction model has been a popular choice with both offshore and onshore sites. Many aspects of construction can be done in a modular fashion from the steel structure through piping and equipment, electrical systems, insulation installation and metal cladding.

While this does require planning and coordination to ensure this pre-fabrication process will work for a specific LNG project at a given site, modularization will typically decrease time in the field, which decreases labor costs. It also helps enhance safety programs, can help increase efficiency in remote and harsh weather locations and can improve construction execution. Modularization is growing in popularity globally, and more LNG projects are beginning to utilize it.

Efficient transportation and construction

Thanks to transportation and lifting equipment, it’s possible for modular construction to be an economic and efficient solution for LNG projects. Modularization helps avoid the traditional method of using a large workforce at one main construction site. Through this approach, less work can be done at the main site, and pre-fabrication and pre-assembly can occur elsewhere, which helps conserve space, time and budget.

Once completed, these pre-constructed modules can be transported, usually via ship, barge and over land, to the main project site to be installed.

Transportation by ship across open water can be challenging. Modules will be exposed to rain water, salt water and moisture from condensation during transportation and corrosion under insulation (CUI) can occur before the modules are put into service.

safety

Worksite safety for LNG projects is a main driving factor for the implementation of a system, particularly regarding on-site construction.

The modularization approach helps allow for lower exposure to field hazards.

This can help lowers a worker’s risk of being injured and interrupting schedules for other areas of the site.

Less labour required

Modular construction can help reduce the amount of labor required on the job-site. This can be especially beneficial in areas with limited labor pools which can make completing a job a challenge. One of the leading drivers for implementing modular construction is the effectiveness at locations with freezing or tropical temperatures.

It may be difficult for sites to compile a team of skilled professionals to work in extreme weather conditions in a remote area. Modularization can help require less time and less workers when work is split between multiple sites.

Costs and convenience

The modular construction method can be more cost-effective than a traditional main site-built project. Aside from requiring fewer workers overall, the economic benefits of modularization can include the project completed in multiple pieces at varying locations, rather than all at once at one main site. This method can cut unnecessary costs and reduce the risk of any safety related accidents and replacements.

When it is time for modules to arrive to the main site for construction, many have found the process more efficient when assembly occurs in one place. First, the modules do not take up as much space when they reach the main location, which means they can be stored until needed. As the modules take up less storage space, more work can be completed in a timely manner. Then, the modules can be moved and installed easily, which plays an important role in the construction process, budget, timeline and standards.

Conclusion

Modular construction in the LNG industry has been proven to be a viable, safe, cost-effective and environmentally friendly solution. It provides for more efficient transportation and construction as well as job site safety. But, it also requires less labour and can reduce overall costs of the project.

FOAMGLAS® cellular glass insulation has been used on the majority of modular LNG constructions projects worldwide. The main reason for this is that we combine the unique blend of physical and insulating characteristics of our material with longtime experience in LNG modular constructions all over the world.