Thermal and waterproofed insulation at Pruszków pool

What can be done to ensure that renovating a swimming pool is not a leap into the deep end? How can thermal bridges be eliminated? How can the risks of condensation be improved through suitable insulation in a flat roof insulation system when renovating a building with extremely high humidity? Let's find out whether the problems of the KAPRA Municipal Indoor Swimming Pool in Pruszków have been solved and what benefits have been achieved through the use of thermal FOAMGLAS® cellular glass insulation.

It is difficult to find a more demanding facility than swimming pools when it comes to moisture protection. Significant internal humidity and high vapour pressure are a real test for the airtightness and water-repellency of structures, particularly thermal insulation materials in walls and roofs. Problems arising from condensation are a common sight in swimming pool facilities, construction of which was at an all-time high in Poland in the 1990s and at the beginning of this century. One legacy of the 'boom' at that time is the KAPRY Municipal Indoor Swimming Pool in Pruszków, which opened its doors on 25 January 2003. Then, almost 20 years later, the facility was in need of renovation.

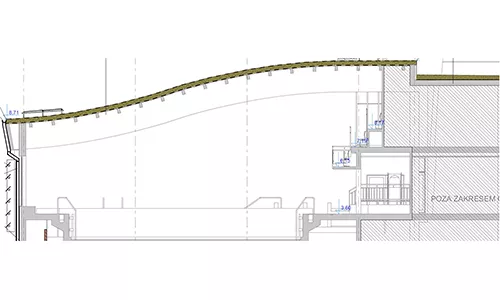

"We were getting comments from staff and customers that something worrying was going on over their heads. The phenomena we observed indicated that the facility might be in danger of having a leaking roof. Due to its age, it was leaking in some places and was slowly coming to the end of its usefulness," recalls Janusz Wierzbowski, (the facility's director and former chairman of the board of the Polish Basketball League). Previously, some ad hoc work had been carried out on the building, but more along the lines of 'mending' faults than actually repairing them. Given the nature and dynamics of the building's use, it was high time to act. The scale of the project, which involved insulating a flat roof of nearly 1200 m² was a real challenge.

THERMAL INSULATION, STABILITY AND STRENGTH OPT FOR FOAMGLAS®

The work, which started in November 2021 as part of the initiative of the Realisation and Investment Department of the Pruszków City Hall, included the repair of the old slides, the replacement of all circuits, draughts and other elements of the ventilation system, as well as the renovation of the external façade and the roof. In the case of the latter, after tearing off the covering layer, it quickly became apparent what exactly was at the root of the leakage and dampness problems.

- The condensation of water vapour both in the roof structure and in the thermal insulation layer itself led to the mineral wool being exposed to moisture for a long period of time, which resulted in the deformation of the panels, an increase in their weight and the degradation of the original thermal insulation properties," explains arch. Szymon Majcherczyk of the Superjednostka Projektowanie studio, which is responsible for the pool modernisation plan.

The priority when replacing the thermal insulation of the roof was therefore to obtain a rigid substrate that would guarantee that the weight and thermal parameters of the partition would remain unchanged throughout the facility's continued use. Due to the load on the air handling units and platforms, as well as the photovoltaic installation planned at a later stage, it was also crucial to ensure the high load-bearing capacity of the roof structure without deformation. A significant obstacle in this aspect, however, was the lightweight timber substrate with its considerable span. the expert report showed that the loads on the structure would be exceeded with the possible use of a ballast system for the photovoltaics.

- The only option seemed to be to attach the installation to load-bearing ligaments. However, this solution was out of the question, as it generates very problematic thermal bridges with standard mineral wool insulation, which in the roofs above the swimming pool halls lead to condensation on the fixings and damage to the roof layers. Assuming a simple replacement of the old insulation layer with new wool panels, the problem of soggy thermal insulation would return sooner or later," adds M.Sc. arch. Szymon Majcherczyk, M.Sc.

FOAMGLAS® AS THE SOLUTION TO COMBAT THERMAL BRIDGES, MOISTURE AND DEFORMATION

Taking these priorities into account, the architects at Superjednostka came up with the FOAMGLAS® Compact Roof Technology. This system not only protects the roof against leaks, but also moisture and horizontal migration of moisture. Thermal insulation panels made of cellular glass became the basis of this system as an extremely durable material with unique properties.

- FOAMGLAS® thermal insulation guarantees non-condensation and complete airtightness thanks to the structure of the closed, hermetically sealed glass cells and the bituminous binder between the individual layers and panels. Here we will not experience any dampness, leaks, development of biological forms or nesting of insects and rodents - explains Łukasz Barcz, expert of FOAMGLAS® Building Poland.

- Combined with the high A1 fire resistance and the 500 kPa compression resistance of the panels, the waterproofing rests on an exceptionally stable substrate with 0% deformation, which translates into long, efficient operation of the membranes and roofing felt. It is also worth mentioning that there is no need for vapour barrier layers in FOAMGLAS® Compact Roof systems.

- FOAMGLAS® cellular glass can successfully serve as a permanent substrate for the equipment, without the need to mount it to the roof's supporting structure. In practice, this is achieved by means of mounting plates which "bite" into the cellular glass panels - the substructures to be screwed onto them, such as photovoltaic systems, are then treated as if they were being fitted to a concrete slab. In this way, we were able to dispense with the ballast structure, which in the context of existing roofs, such as the one at the swimming pool in Pruszków, practically determines the possibility of using photovoltaics," adds M.Sc. arch. Szymon Majcherczyk, M.Sc.

It is worth emphasizing at this point that the solution applied allowed the investment to be phased - the mounting plates embedded in the thermal insulation layer enable the managers of the KAPRA Municipal Indoor Swimming Pool in Pruszków to install photovoltaic panels at a later date, thus making it possible to spread the investment costs over time.

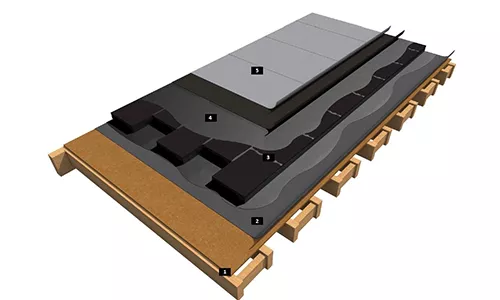

THE FOAMGLAS® COMPACT ROOF SYSTEM USED AT KAPRA SWIMMING POOL

- Wooden substrate

- Separation layer

- FOAMGLAS® T3+ boards laid on hot bitumen, joints between boards also filled with hot bitumen.

- Priming layer of hot bitumen

- Waterproofing layer of classic bitumen membranes - primer and UV top-cover.

- The FOAMGLAS® T3+ panels were laid in two layers, 130 and 100 mm thick, and then bonded to each other and to the substrate using hot bitumen. Despite their high strength, the boards are lightweight and easy to install, and the absence of mechanical fasteners, which would pass through the thermal insulation layer and the roof substrate itself, has made it possible to eliminate the risk of thermal bridges and water vapour penetration," mentions Daniel Cymerski of PBN Invest, the company responsible for providing technical and commercial support for the project.

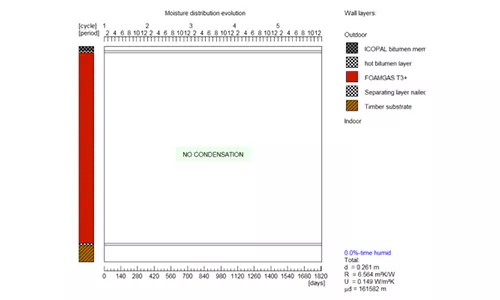

MEASURED PARAMETERS OF THE NEW ROOF OF THE KAPRA SWIMMING POOL

- Total thickness of roof structure: 261.2 mm

- Thickness of thermal insulation: 230 mm

- Thermal insulation board thermal conductivity coefficient (λ): 0.036 W/mK

- Roof thermal transmittance (U): 0.149 W/m2K

- Water vapour diffusion resistance coefficient of the thermal insulation µ = ∞ (vapour tight)

- Point loads: ≤ 1.5 mm

- Compressive strength: ≥ 500 kPa

- Flexural strength: ≥ 450 kPa

- Tensile strength: ≥ 150 kPa

- Fire reaction class of thermal insulation: A1 (also B-ROOF T1 for the system)

- Melting point of thermal insulation: > 1000°C

- Melting point of thermal insulation: > 1000°C

FLAT ROOF INSULATION REALISED IN THE MIDDLE OF A PANDEMIC

Swimming pools, water parks, wellness centres - although we all associate them with pleasant leisure activities, they are often a source of frustration for managers and owners, lost time and, what is worse, huge financial losses caused not only by recurring renovations, but also by the need to close the facility for some time. In the case of the KAPRA Municipal Indoor Swimming Pool in Pruszków, the work to insulate the flat roof, combined with the removal of thermal bridges, fell into the pandemic period, which triggered some additional difficulties.

- Something that two years back was available practically on the spot, now required up to several months of waiting. For example, the contractor for replacing the jacuzzi communicated that the shortest delivery time would be around six months," recalls Janusz Wierzbowski.

- As for the roof, the whole thing went extremely smoothly. There was no problem with the availability of FOAMGLAS® thermal insulation panels, and we are also very satisfied with the cooperation with the contractors and the entire technical and commercial service for the project. Despite delivery delays and unpleasant situations that took us by surprise during the retrofitting of the other elements, we were able to complete all activities in May 2022.

IT IS WHAT YOU CANNOT SEE THAT OFTEN MATTERS MOST

The investor's and manager's feelings after all the work has been completed are clear: the modernisation of the KAPRA Municipal Indoor Swimming Pool in Pruszków has been a complete success.

“The facility has taken on a shine and the new equipment has brought a breath of modernity. We hear from customers, especially families with young children, that they are very impressed with, among other things, the pontoon slide, which makes it possible to slide down together," explains Janusz Wierzbowski.

- What we, as the facility's owners, are particularly pleased about is what the customer doesn't see - i.e. that the roof is made of very good insulating materials, ensuring many years of use.

“In the future, we would like to create a spa area within our facility, which would be another attraction for the residents of Pruszków. I hope that the city will make the right choice when it comes to future investments and will once again rely on FOAMGLAS® thermal insulation solutions," concludes the pool director.