Key factors that affect material selection in LNG service

LNG is a mixture of low-molecular-weight hydrocarbons that has been cooled down to liquid form for ease and safety of non-pressurized storage or transport. Multiple critical factors should be evaluated to determinate whether an insulation system should be considered for LNG service.

Demand for Clean Energy

and industrial insulation systems

The recent surge in demand for energy, clean energy in particular, catalyzed a positive series of events for companies specializing in the manufacture, fabrication , and installation of high-performance industrial insulation systems. The sheer volume of insulation required to protect the high investment in these facilities has been inspiring.

The two biggest enemies of industrial insulation performance, moisture (liquid and vapor) and fire, are prominent in the engineering of liquefied natural gas (LNG) handling facilities. These issues need to be taken on separately with engineering of materials, but the good news is that the issues can be integrated for solutions.

Moisture Vapor transmission

It stands to reason that with most of these plants existing in hot and humid climates, the need for moisture vapor transmission (MVT) resistance is paramount. MVT can be excessive in these design conditions. The pipe or vessel may be at a continuous operating temperature of nearly-270°F (-168°C), and the ambient conditions are at 90°F (32°C) or more with humidity of 90 percent. In these conditions, the opportunity for moisture to be driven into the insulation is at its highest possible level. Since the natural moisture drive is from heat to cold, one can see how the material and application selections can make or break the system.

Fire risks

proper material selection

LNG is a mixture of low-molecular-weight hydrocarbons. The actual composition varies; however, LNG is primarily methane with ethane, propane, butane, and nitrogen present as well. Obviously, there is significant fire potential with LNG. The risk of fire can be reduced by proper material and application selection. Often, there are fire credentials critical to evaluating whether an insulation system should be considered for LNG service. These may include but are not necessarily limited to the National Fire Protection Agency (NFPA), the Coast Guard Approval (critical near or offshore), Underwriters Laboratories (UL), and Factory Mutual (FM).

Other key factors that affect material selection

- Dimensional stability: Cold or cryogenic service temperatures can cause dimensional channel changes leading to warping of the insulation on the pipe, leaving gaps. In concert with high humidity, this can promote moisture entry that will promote ice buildup. This can be an expensive problem to repair.

- Compressive strength: Construction and maintenance of LNG pipe racks require tradesmen to work on and around the insulation. Physical damage is avoided by using insulation materials with high compressive strengths, absorbing the point loads and traffic. In addition, high compressive strengths are required for pipe supports, as the weight loads can damage insulation at those locations.

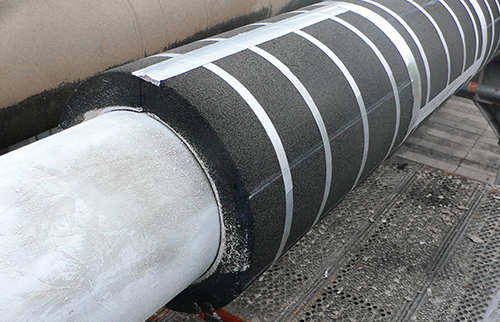

- Combustibility: Often fire protection is an additional consideration for the system. This requires the use of fire-rated materials, usually including stainless steel jacket and banding. This information is critical to the selection of the proper materials.

- Accessories selection: Selecting accessory materials that complement the insulation is also critical. Because this application is critical and highly costly, the selection of proper accessories cannot be done in haste. Lab data is simply not enough. Extensive testing and proven performance history with the specified insulation are highly recommended.

- Insulation fabricator selection: Attention to detail in fabricating insulation for cold and cryogenic work should never be understated. Paying close attention to dimensions, specifically minimizing through-fabrication joints (joints perpendicular to the pipe that pass through the entire thickness of the pipe insulation segment) and 100 percent sealing of those joints will contribute to a successful project. It is suggested that a fabricator demonstrate the proper experience with cold and especially

cryogenic work before an order is placed with them. As these projects tend to be very large in scope, the fabricator's capacity for sourcing materials and converting those materials into quality insulation systems is an important consideration as well. - Contractor selection: There are highly competent contractors familiar with the critical cold and cryogenic insulation techniques. These companies are staffed and managed around performance in critical end uses, of which LNG is certainly one. The bid list may not be as large as one would like, but competence should win the day with LNG candidates. Historical profiles and accessible reference lists should be the minimum for pre-qualifying an LNG insulation contractor.