Key differences between FOAMGLAS® & other insulation materials

When it comes to insulating your buildings and infrastructure, making the right choice can have a significant impact on energy efficiency, durability, and overall performance. Find out how FOAMGLAS insulation differs from other commonly used insulation materials on the market.

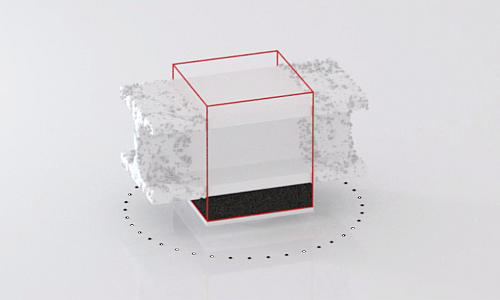

Waterproof versus water-repellent

Mineral and plastic insulation is water-repellent. With its structure of millions of sealed glass cells cellular glass insulation is absolutely waterproof. Cellular glass insulation remains dry through all weather, even during flooding. Cellular glass retains its original insulating performance whatever the wet conditions.

In 2017 an independent FIW* study based on samples collected from buildings insulated 50 years ago, showed the insulation remained as effective as the day it was originally installed. Early renovations are unnecessary, long term costs are reduced, and energy is saved. Cellular glass insulation helps to protect your building envelope against water ingress.

* FIW: research institute for insulating materials – Munich

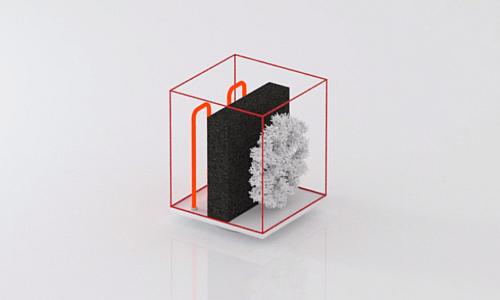

Vapour-proof versus vapour-absorbent

Insulation materials with a vapor-absorbent structure do not offer any protection from condensation. When condensation occurs within the insulation material, most of the thermal performance is lost; condensation leads to an accelerated ageing process in any material that becomes damp. Over the years insulation materials need to be replaced to ensure long term building efficiency.

Within any building, irrespective of the building structure or building use; condensation can occur, causing both structural corrosion and surface damage, jeopardizing the building’s stability, and commercial value.

Plastic insulation materials are good insulations; but are not completely vapour tight. They are used with adhesive jointing tape or additional Vapour Control Layer.

Cellular glass insulation is completely vapour tight, with a water vapour diffusion resistance factor of infinity. There is no risk of condensation penetration, into the insulation or into the construction. The material will not swell or be affected by mould. When vapour proof adhesives and sealants are used the cellular glass insulation does not require an additional vapour control layer.

Performance under pressure

The compressive strength is the load bearing capability of a material without the material compressing. It is expressed as force (kN) divided by area (m²) = kPa.

The European standard EN826 determines the compressive strength of insulation materials, whilst allowing up to 10% compression before the load bearing capability is recorded. Most insulation materials are tested according to this European EN826 standard. As building thermal performance has increased, so has the insulation thickness. Today an insulation thickness of 200mm is not unusual.

Therefore, under the EN826 conditions, 20 cm of insulation will compress by 2 cm, leading to tension in the waterproofing membranes, resulting in splits and cracking.

FOAMGLAS® cellular glass insulation is tested to EN826 Annex A, a test where compression under load is not allowed. With cellular glass insulation, there is no movement under compressive load, or tension in the waterproofing membranes. The waterproofing will perform as intended. The cellular glass insulation helps to protect the building from water ingress.

Why is this important?

Architects, engineers and contractors face major challenges when the insulation upon a floor or roof must also be able to withstand heavy loads from parked cars, maintenance, service or emergency vehicles, If the insulation layer moves, paving, finishes, and waterproofing will fail. Water enters the roof system and insulation performance is lost.

With cellular glass insulation, there is no movement under compressive load, paving, finishes and waterproofing will perform as intended. The cellular glass insulation helps to protect the building from water ingress.

Thermal movement

Materials shrink with cold and expand with heat. The thermal expansion coefficient indicates the extent to which this happens. Here are examples of the thermal expansion coefficients of a few building materials:

- Insulation:

Plastic insulation: 50 - 70 x 10-6/K

Cellular glass insulation: 9 x 10 -6/K

Stone wool: 7 x 10-6/K

- Other building materials:

Aluminium: 23 x 10-6/K

Concrete: 10 x 10-6/K

Steel: 12 x 10-6/K

The lower the expansion coefficient, the less the material shrinks or expands with changing temperatures.

What does this mean for thermal efficiency, and reliability of the waterproofing?

A high thermal expansion coefficient has an impact on the dimensional stability of an insulation system. Insulation installed during warm weather, will shrink causing open insulation joints leading to cold spots within the insulation system; having major consequences for the buildings insulation performance and energy efficiency.

Insulation installed during cold weather, will expand causing a stretching of the roof membrane. The thermal movement of the insulation causes the roof membrane to age faster than expected.

Effect on fixing methods

For insulation materials which have a high rate of thermal movement, that are sensitive it is best to use mechanical fixing methods. When these insulations expand and contract vapour control layers and waterproofing membranes are subjected to pressure or tension.

Despite the mechanical fixings, the formation of wrinkles, and stretching can be seen on hot and cold days, causing extra stresses, reducing the membrane’s lifespan. Mechanical fixing involves numerous penetrations through the insulation system to causing thermal bridging, and the potential for water ingress.

The thermal expansion coefficient of cellular glass insulation is similar to concrete and steel. Installing cellular glass is quick and simple. Cellular glass is secured into place using adhesive. The waterproofing is not subjected to the stresses associated with expansion and contraction of the insulation system. There are no thermal bridges or penetrations though the insulation system.

FOAMGLAS® cellular glass insulation significantly reduces thermal bridging, improves thermal efficiency and extends the service life of waterproofing membranes, and associated seals and perimeter closures.

Resistant to chemicals and vermin

The structure and chemicals used in various mineral and plastic insulation materials, makes them susceptible to various bacteria, parasites, solvents, acids, and alkalis, used in the construction industry and found on polluted and contaminated ground. These insulations also become nesting material for various vermin and insects.

Cellular glass insulation is glass, and therefore inorganic. It does not rot or attract living organisms. It is unaffected by hydrocarbons and is impervious to radon gas. Cellular glass remains intact. Even forty or fifty years later!