Information for the Installers

Proper installation is key to getting the most out of FOAMGLAS® insulation.

Technical Guidelines

Our FOAMGLAS® Technical Guidelines offer comprehensive insights into the essential criteria for installing FOAMGLAS® applications. These guidelines cover various aspects, including specific criteria for different surfaces.

For instance, they outline the minimum requirements for a steel deck surface, detailing not only the thickness of the steel deck but also providing specifications for the maximum allowable deflection, minimum adhesive surface area, and an overview of the minimum thickness of the FOAMGLAS® system based on trough width. Additionally, the guidelines specify the maximum permitted irregularities for continuous substrates, ensuring precise installation standards.

Installation Instructions

For optimal results and long-lasting insulation, it is crucial to follow the proper installation instructions.

1.Before beginning the work, it is important to conduct preliminary checks on the FOAMGLAS® TAPERED plan. This includes carefully comparing the dimensions, parallelism, angles, and location of water outlets. If necessary, reference line drawings should be used for accurate comparison.

2. When preparing the deck, certain criteria should be followed:

- The substrate must be clean, dry, and free of any irregularities. Irregularities should not exceed 3 mm over 600 mm or 5 mm over 2 m.

- If the substrate is concrete and needed, an appropriate leveling screed should be applied.

- In the case of pre-cast concrete beams, irregularities between each section must not exceed 3 mm.

For concrete/timber decks, any surface unevenness underneath a slab should not exceed 3 mm to minimize bitumen/adhesive consumption. Failure to meet this condition will result in increased consumption.

For metal decks, the suitability depends on distinguishing unavoidable unevenness from those that can be improved.

3. Where to begin laying the materials:

To avoid stepping on insulated areas, start opposite to where bitumen/adhesive (and other materials brought up by hoist) are supplied.

- Starting from a water outlet allows for circular or fan-shaped work with minimal preliminary measurements. However, consider potential blockage of water during rain if there are no other rainwater outlets nearby. The prevention of leakage relies on the quality of the FOAMGLAS® Compact Roof application.

- Starting from a ridge offers advantages such as the "D" layout tapered system (pyramid shape) and protection against water blockage in case of shower rain. Adjustments are made only when reaching the perimeter.

- Starting from an edge or corner is also possible if there is a water run-off point situated opposite. This method is considered safest and recommended to prevent any water blockage before completion.

Making a Hole in FOAMGLAS® insulation material

If you need to make a hole in FOAMGLAS®, it is essential to follow specific guidelines to maintain its integrity and insulation.

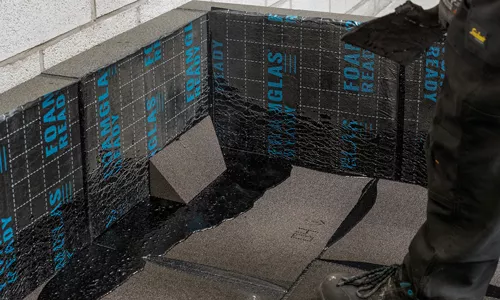

Angle Fillet

Angle fillets play a significant role in achieving proper sealing and insulation around corners and edges.

FOAMGLAS® TAPERED for reduced material usage and long-term value

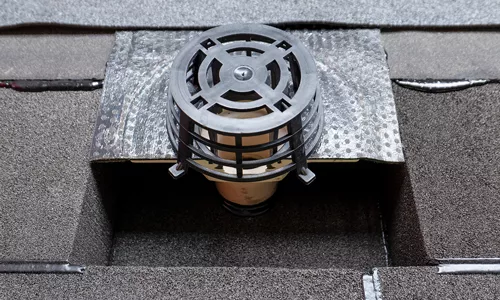

Flat Block to Allow Drain Installation

For effective drainage, the use of a flat block around water outlets is necessary during FOAMGLAS® TAPERED installation.