How to reduce thermal radiation from LNG pool fires

Industrial fire safety is a concern for plant owners, and exploring innovative technologies for helping to keep people safe and protecting equipment assets is a priority for many high-profile industrial plants around the world. Owens Corning's Pool Fire Suppressant system helps keep pool fires at bay, is designed to improve the overall safety of facility personnel, and helps prevent damage to equipment and resources.

The FOAMGLAS® PFS™ system has been used throughout the world for the suppression of LNG pool fires for almost 40 years. However, the next generation system, appropriately referred to as the FOAMGLAS® PFS™ Generation 2 pool fire suppressant system recently introduced has increased safety measures and the speed at which pool fires are contained. This patented1 system is designed to improve overall safety and helps prevent damage to equipment and resources.

1 U.S. Patent No. 9,925,401: Cellular glass system for suppression of vaporization, fire and thermal radiation from liquid hydrocarbons

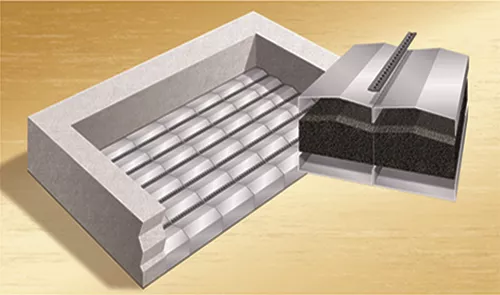

This passive fire suppression system includes a tapered design to promote drainage and channel liquids from the upper surface to below the system. The drainage is beneficial for both environmental conditions, such as rain, as well as for incidents where combustible liquids are spilled on the surface of the system. Therefore, the system will not only shield combustible materials that are under the system, but it will also quickly drain combustible liquids that may spill onto the top of the system to the lower surface.

The threat of pool fires

When spills occur from low-source pressures, they can be conveyed safely to an impounding area or a sump to minimize the size of the resulting flammable vapor clouds as the cold LNG boils on the warmer ground. Pressurized releases of LNG may produce liquid sprays or flashing jets, which can create larger flammable vapor clouds.

Pool fires are common accidents that occur in the LNG industry and can be ignited within seconds by something as simple as lighting a match or static electricity. These pool fires may cause additional fires to break out and ultimately put human lives in danger. Because of this, companies are making the installation of safe and effective pool fire suppression systems a priority.

The first generation

The first-generation system involved the use of nonflammable FOAMGLAS® insulation cubes packaged in UV-resistant, easy-to-handle bags. These bags are designed to rise to the surface of the LNG to insulate, reduce vaporization and decrease the surface area available to the fire. The FOAMGLAS® insulation PFS™ cubes are released and float onto the surface of the pool to lower the flame height and thermal radiation.

After widespread adoption of the Generation 1 system, the FOAMGLAS® PFS™ Generation 2 system was introduced to address requirements for extended resistance to weathering and poor climatic conditions, as well to improve the working surface for easy snow removal.

The second generation

The FOAMGLAS® PFS™ Generation 2 system shares similarities with the first-generation version in terms of overall functionality. Durability improvements made for Generation 2 make it easier to maintain and effective in containing pool fires, while helping to protect employees and equipment.

The FOAMGLAS® PFS™ Generation 2 system complements safety programs by delivering a reliable, low-maintenance passive solution for the reduction of thermal radiation and flame height in contained LNG fires. The system is easy to install and can provide immediate mitigation of the thermal flux, rate of combustion, view, and overall size of a LNG pool fire.

Each system features FOAMGLAS® cellular glass insulation, which has a combination of physical properties not found in traditional fire suppressant foams. The material is extremely buoyant and nonflammable. It is non-corrosive, resistant to vermin and has a high compressive strength.

The new system also provides a sleeker, more polished look compared to the bags used in the first version. Each of the interconnected modules are made of a cladded insulation core and assembled in an orderly fashion to cover the containment area with one continuous, buoyant, passive fire suppressing system.

how it works

The FOAMGLAS® PFS™ system is a passive system that remains in place to assist in providing immediate and automatic control of LNG pool fires without deployment delays.

Because the FOAMGLAS® PFS™ system is highly buoyant, the pool fire suppressant modules rise immediately to the surface of the LNG to provide an insulating cap that can aid in reducing vaporization.

In the event of ignition, the FOAMGLAS® PFS™ modules quickly limit thermal radiation and flame height. The system works in conjunction with fire-fighting foams.

Testing for proven results

- FOAMGLAS® PFS™ systems have undergone extensive application testing and trials. Vapor and fire control testing2 commissioned by TOTAL and conducted under the supervision of Resource Protection International at the Centro Jovellanos concluded that the FOAMGLAS® PFS™ system was effective in reducing radiant heat flux and controlling LNG and LPG pool fires.

- Additionally, field extinguishing trials were successful in demonstrating the system’s performance. These trials, performed on an LNG test pit of 100 ft², showed that firefighters equipped with a single 20 lb. dry chemical extinguisher were able to directly approach the edge of the containment pit and extinguish the flames within seconds with only a partial charge.

- In other scale tests conducted by Shell Research Ltd3, a depth of 200 mm of cellular glass assisted in providing an immediate and automatic control of the fire at a level comparable to 1 – 2 m of high-expansion foam.

- Results of large-scale experiments4 performed at the Emergency Services Training Institute of Texas A&M University have shown that the view factor of an LNG pool fire suppressed by a FOAMGLAS® PFS™ system is comparatively lower than that of high expansion foam, providing real protection from thermal radiation for exposed equipment or personnel. With maximum flame height significantly reduced at a steady state, the thermal radiation is limited to the visibility within the much lower temperature range of 200°C – 500°C (392°F – 932°F).

2: Resource Protection International. "Vapour & Fire Control Testing of FOAMGLAS® PFS System (Gen 2) on LNG". Feb. 2014

3: Lev, Y,. Shell Research Ltd., Thornton Research Centre, “A Novel Method for Controlling LNG Pool Fires”, Fire Technology

4: FOAMGLAS® Insulation on LNG. MKOPSC. Texas A&M University