Fire performance of FOAMGLAS® insulation systems

The goal of fire endurance testing of a mechanical insulation system is to demonstrate that the system will help to prevent a pipe or piece of equipment from reaching a specified temperature too quickly. Since thermal insulation only reduces the rate of heat transfer, rather than stopping it, insulation material type, thickness, layering, cladding and tertiary materials are important in determining the overall level of prevention.

Specifying insulation systems that effectively contribute to passive fire protection for steel structures has the potential to save lives in the event of a hydrocarbon-based fire or explosion. Such systems contribute by providing valuable extra time for worker evacuation, the activation of first responders and can aid in the prevention of structural collapse caused by fire.

FIRE PERFORMANCE TESTING

Fire testing is a means of determining whether fire protection products meet minimum performance criteria as set out in dedicated norms and standards.

Different testing methods are used to determine the reaction of a product in terms of fire resistance, flammability, smoke opacity and toxicity when exposed to a fire.

Meeting these performance criteria allows for the safe specification of suited products in fire protective systems.

Combustibility

ASTM E 136 – Behavior of materials in a vertical tube furnace at 750 °C (1382 °F)

EN 13501-1: Fire classification of construction products and building elements

These tests consider the combustion and heat generating characteristics of building materials. Testing continues until specimen thermocouples reach 750 °C (1382 °F) or until specimen failure. Visual observations regarding flame and smoke are made throughout the test.

A material passes if three or four specimens: (1) do not have thermocouple temperatures more than 30 °C (54 °F) above the furnace temperature; (2) show no flaming after the first 30 seconds; and (3) show no temperature rise or flaming when specimen weight loss exceeds 50%.

The main purpose of the test is to classify a product as Noncombustible (ASTM E136) or as A1 or A2 Noncombustible according to the European classification system (EN 13501-1).

It is important to understand that these different international systems are not equivalent or interchangeable.

FOAMGLAS® insulation systems have been tested in accordance with both standards and have been classified as noncombustible (ASTM E136) and Euroclass A1 – Noncombustible (EN 13501-1).

Flame Spread and Smoke Development

ASTM E 84 – Standard Test Method for Surface Burning Characteristics of Building Materials

This test compares the surface burning properties of building materials regarding flame spread and smoke development to standard materials (i.e. red oak and inorganic cement board). In a horizontal furnace, gas burners direct flames against the sample. At the beginning of a test, base readings are observed, and, during the test, photoelectric cell output is recorded at least every 15 seconds. At the test’s conclusion, chamber conditions are observed, the sample is further examined, and flame spread distance, temperature and changes in the photoelectric cell readings are plotted.

Testing of FOAMGLAS® insulation has shown that flame spread and smoke development were both nonexistent when tested in accordance with ASTM E84. This is also why it is often a preferred insulation material for densely populated commercial and institutional buildings where fire and smoke spread are key issues.

hydrocarbon fire

UL-1709 – Rapid Rise Fire Tests of Protection Materials for Structural Steel

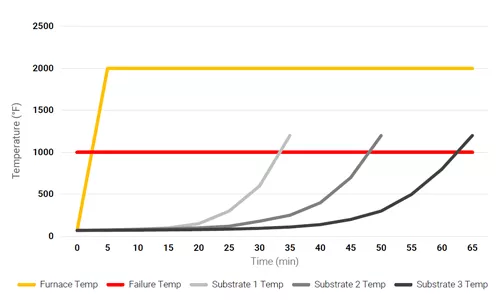

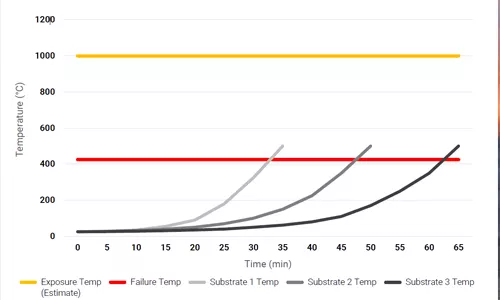

This test is specially designed to create the unique conditions of a petrochemical plant fire and measures the hourly protection afforded steel during a rapid temperature rise that reaches 1093 °C (2000 °F) within five minutes. Additionally, the fire environment within the furnace is to develop a total heat flux of 204 kW/m² (65,000 Btu/h·ft²) within that time frame.

The burning rate and fuel energy potential here are totally different from fires involving typical building construction materials. As with the previous test, performance is based on the ability of a material to limit the temperatures measured on a structural steel piece in a furnace environment to an average value of 538 °C (1000 °F). The amount of time before failure occurs dictates the time rating of the protection granted by that insulation or insulating system.

Protection against hydrocarbon-fueled fires can sometimes benefit from a combination of different materials to form a system best suited for that environment or application.

It is also for this reason that we recently have tested our FOAMGLAS® insulation products in accordance with UL 1709 but also tested common combined systems that are sometimes specified for environments.

The systems tested included single and double layer FOAMGLAS® insulation systems as well as common combined systems including mineral wool and ceramic fiber.

The duration of passive fire protection ranged from 30 minutes with a single layer FOAMGLAS® insulation system to 3 hours when combining it with Owens Corning® mineral wool insulation.

Jet fire

ISO 22899-1 – Determination of the resistance to jet fires of passive fire protection materials – part 1 – general requirements.

The jet fire test focuses on material response to directional or intensive and localized fire events.

During the test, insulation or the insulating system is exposed to 14 Megawatt (0.3 kg/sec) horizontal flames produced by a propane fuel system projected out of the standardized jet nozzle for various time periods, depending on the rating, to simulate the intense jet fires that hydrocarbon facilities can face.

Jet fires are a significant hazard for the oil and gas industry and can cause injuries to personnel and failure of equipment and structures.

This is also why we recently tested our FOAMGLAS® insulation products and common combination systems in accordance with ISO 22899-1.

The systems that were tested comprised single layer and double layer FOAMGLAS® insulation systems.

In addition, composite systems of FOAMGLAS® insulation with ceramic fiber, mineral wool or the use of an intumescent coating were also tested.

FOAMGLAS® insulation provided up to 30 minutes of protection for encased materials; however, incorporating Owens Corning® mineral wool provided up to two hours of protection and combining FOAMGLAS® insulation with an intumescent material provide up to four hours of protection during jet fire testing.

Conclusion

Passive fire protection is a tested and proven method to help address the fire risk at hydrocarbon processing facilities. Insulation systems can contribute to fire protection by providing heat absorption and thermal protection to reduce the rate of temperature rise towards the item being protected.

When specifying insulation systems for passive fire protection of structural steel, equipment, piping and hydrocarbon storage tanks, engineers should consider relevant material properties, the process environment and the required level of fire protection.

Materials properties such as combustibility, absorbability, smoke development and possible loss of mass in case of a fire can help determine which products would be most suited for a set of design considerations and environmental conditions.

The process conditions and specified level of passive fire protection should determine which insulation systems would meet the fire protection performance criteria for a specific piece of equipment or tank.

Thoroughly selecting a system or combination of insulation materials tailored to the environment and application can help lengthen the time that materials perform in case of a fire. Specifying insulation systems that effectively contribute to passive fire protection has the potential to save lives in the event of a hydrocarbon-based fire or explosion.

Such systems contribute by providing valuable extra time for worker evacuation, the activation of first responders and can aid in the prevention of structural collapse caused by fire. Additionally, they also help safeguard valuable installations that drive essential processes which helps to maintain the continuity of the facility.