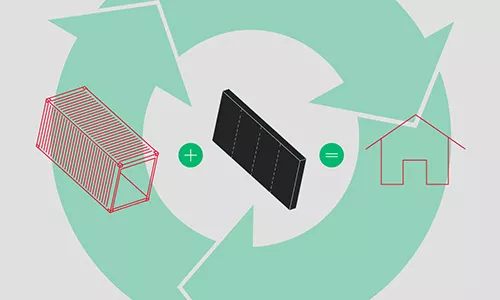

FOAMGLAS® insulation helps transform shipping containers into homes with 50% lower carbon footprint

FOAMGLAS® business takes part in the cHOMgenius project, which converts shipping containers into energy-efficient homes that are easy to modify, disassemble and reassemble. We listed three reasons why cHOMgenius can change the whole concept of living.

1. Circularity

Transforming a problem into a resource. That is the core of the cHOMgenius project, which reuses discarded shipping containers and transforms them using modular construction into flexible and energy-efficient housing that can be adapted to various functions and needs.

The project, led by DABC-Politecnico di Milano with the team of Professor Elisabetta Ginelli and partially funded by the Smart Living Project of the Lombardy Region in Italy, brings together a large number of actors and companies, including FOAMGLAS. All are united by one goal: to develop new, more sustainable ways of living and building. That is why the project does not exclude the use of other, dry-assembled construction systems –metal or mixed –designed ad hoc for special productions.

FOAMGLAS Italy’s Area Manager Claudio Saponaro is pleased that circularity plays such a central role in the project. It was him, together with Prof. Ginelli, who originally proposed the idea of researching customizable, easy-to-assemble and energy-efficient housing.

“Globally, there are many projects that involve disused containers, but none of them have the characteristics we have been able to achieve. The cHOMgenius house is assembled from prefabricated structural modules that are easy to disassemble and reuse in another location and building.”

2. Energy efficiency

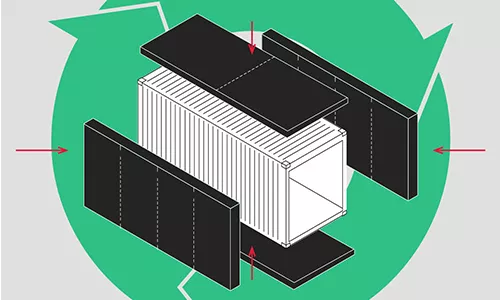

The cHOMgenius project rethinks the way we will live in the future, so energy efficiency is considered at every stage. One of the main solutions is the use of FOAMGLAS® cellular glass insulation for insulating the building's foundations, roof modules and wall modules.

“FOAMGLAS® insulation offers comprehensive protection for the building, and it is an indispensable part of the project. It allows the use of different roof types, such as flat, green and solar. Once installed, FOAMGLAS® cellular glass insulation retains its properties and enhances energy efficiency for the entire lifetime of the building”, says Claudio Saponaro.

The cHOMgenius prototype is designed to be an off-grid system, thanks to coordinated systems that include a heat pump, cogenerator, solar panels, electric cells, inertial accumulation and low-voltage electrical systems.

All construction materials have been carefully selected to ensure the inclusion of only products with the lowest possible environmental impact. This is also reflected in the end result: according to the LCA report, the carbon footprint of a cHOMgenius house is 50% lower compared to that of a traditional building.

3. Simplicity

While many of the solutions and innovations developed by the cHOMgenius project are the result of a complex design process, the beauty of the project lies in the simplicity of its end product: the cHOMgenius house is quick and easy to assemble. The ease of installation was also one of the additional reasons why FOAMGLAS® cellular glass insulation was selected for the project.

Although cHOMgenius is still at the prototype stage, it is already envisaged that it will be suitable for use as both long-term family housing and emergency shelters in crisis zones. Claudio Saponaro estimates that in crisis areas –for example, in flooded areas –an emergency version of the house can be set up in a few weeks depending on the transport systems available, the site and the degree of modularity chosen.

From the outset, the design has been based on the idea of modular construction: the components should leave the factory as finished as possible, to be transported to the building site. From these prefabricated components, it is possible to assemble a wide range of different combinations and dimensions according to needs and desires, and also taking into account predefined load-bearing systems, whether they are shipping containers, metal or mixed structures.

“cHOMgenius houses are flexible and adaptable to various performance and architectural requirements, as well as different budgets and finishings. The first commercial agreement for production and marketing could be reached during the year 2022”, says Saponaro.