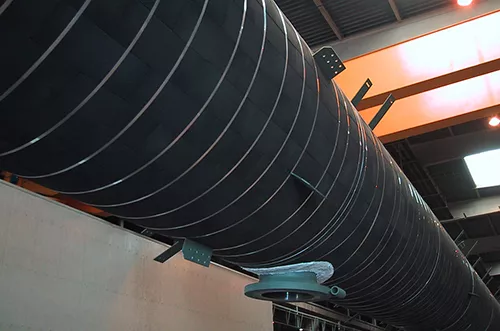

Above ambient process piping and equipemt

Thermal insulation solutions for piping and equipment operating at above ambient temperatures. Our systems limit heat transfer provide mechanical, moisture and corrosion resistance so that process control is assured and energy costs are kept at a minimum.

The requirements to take into consideration with above ambient piping and equipment are the limitation of surface temperature to avoid burns, the heat transfer for economic reasons and the control of the process. In particular conditions, a fire protection requirement may also require a certain insulation thickness.

Although less known, problems due to water or water vapor may also occur in hot insulation systems, in the part of pipe coverings situated near the jacket when the temperatures are lower than 100°C (212°F). The consequences of water vapor intrusion and its condensation may include degraded thermal performance, poor temperature control and increased corrosion risk. When the insulation material absorbs water that can turn to vapor or steam, it affects energy consumption, surface temperature, personnel safety, and operating costs and constitutes one of the major factors leading to steel corrosion.

The absorption of combustible liquids in insulation can create a very serious fire hazard. Absorbent insulations have "the ability to store large quantities of combustible liquids should a leak occur". This leakage and accumulation may often go undetected until ignition takes place. Such a fire could present a serious threat to personnel, property and production.

Installing a closed cell insulation system such as FOAMGLAS® insulation can help prevent moisture and flammable liquids from penetrating the system. This means the system can keep performing without any hazards or increased energy consumption. This can help create safer working environments for your workforce with installations that run more efficiently and economically.

- One or several layers of FOAMGLAS® cellular glass insulation.

- A possible anti-corrosion layer applied on the insulated surface.

- A possible anti-abrasive layer if required.

- A fabric reinforced coating or metal jacket.

Legal notice

The information relating to the products and systems contained on this website is provided in good faith and for general information purpose only. Such information is in any event subject to our product’s legal notice, the content of which users are invited to acknowledge under the following link: Legal Notice