FOAMGLAS® Cryo Spill™ System

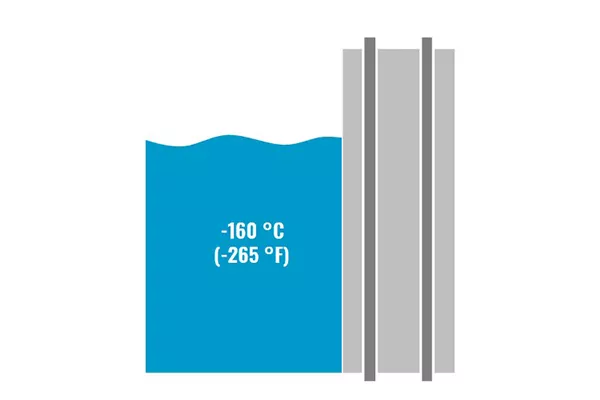

Cryogenic Liquid Spill Protection

In the event of a cryogenic liquid spill, the FOAMGLAS® Cryo Spill™ System can help reduce the rate of vaporization and provide thermal shock protection to concrete and steel.

Combine this system with the FOAMGLAS® PFS™ System for optimal vaporization reduction and fire suppression.

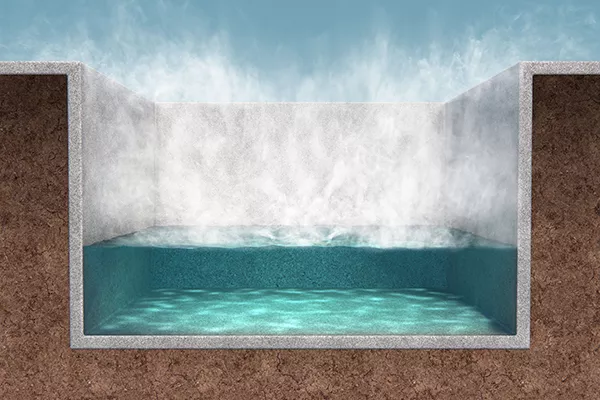

Vaporization

When cryogenic liquid hydrocarbons spill (such as LNG) the liquid can vaporize and generate invisible, and potentially flammable clouds of gas. Water vapor generated during an LNG spill may indicate the presence of a flammable cloud of vaporized gas.

This vapor can travel away from a pit or container before reaching its flammable concentration (5-15%) and ignite. These conditions make LNG pool fires a serious industry concern.

Thermal Shock

When rapidly exposed to cryogenic temperatures, both concrete and steel can experience structural changes that result in a reduction of load bearing capacity.

At freezing temperatures, concrete can experience contraction of the solid network as well as expansion of freezing water within the structure, both of which can lead to microfractures. Likewise, support steel may become brittle at cryogenic temperatures, increasing the risk for fractures to occur.

If pit walls are left exposed, it may require the use of cryogenic steel for reinforcing rebar, significantly increasing costs over traditional steel.

By protecting concrete walls from reaching cryogenic temperatures, traditional steel rebar may be viable for use.

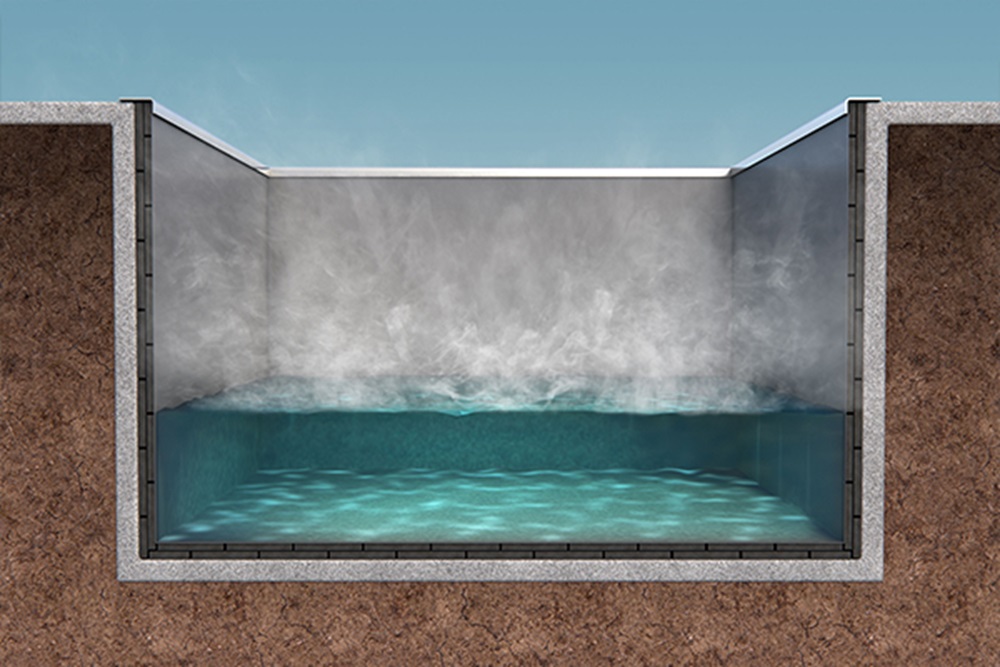

How it works

In a cryogenic liquid spill, extremely cold liquid is exposed to various heat sources such as: warm air, solar radiation and warm ground/concrete.

The cold liquid begins to boil off as heat from these sources transfers into it, resulting in a flammable vapor cloud. These fumes create a fire hazard, and can be blown towards nearby ignition sources.

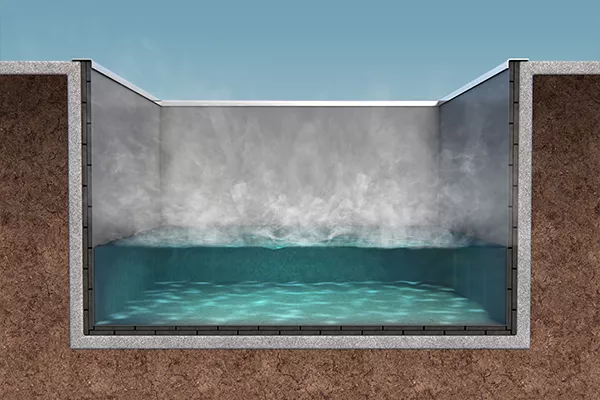

By insulating all areas of entry for heat into the liquid, this rate of vaporization can be greatly reduced.

Heat into the liquid from the ground and concrete can be mitigated by installing the FOAMGLAS® Cryo Spill™ System.

This system also helps protects the concrete and steel from thermal shock.

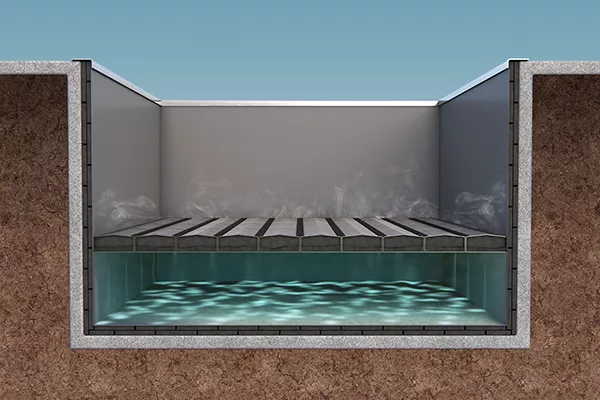

Combined with the FOAMGLAS® PFS™ System

Heat from warm air/solar radiation can be mitigated by utilizing the FOAMGLAS® PFS™ pool fire suppression system.

The system remains in an empty containment pit until LNG enters, at which point the modules are designed to uniformly rise to the top of the liquid where they act as an insulating cap to help reduce vaporization. Should ignition occur, the insulating cover significantly helps reduce radiation and flame height.

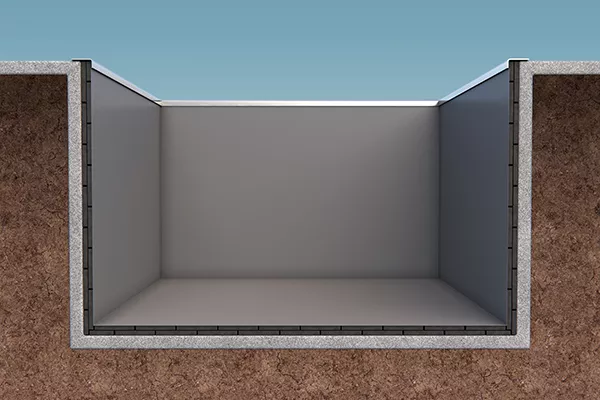

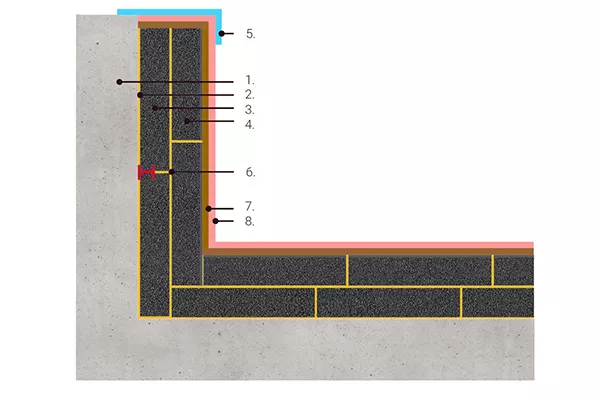

System Configuration and Accessories

1. Containment pit

2. PC® adhesive

3. FOAMGLAS® insulation

4. FOAMGLAS® insulation with PC® 700K reinforced coating

5. Metal flashing

6. PC® F Anchor

7. Protective coating

8. UV coating

Application Photos

Contact our technical team for a variety of services including an Energy Analysis Report for your specific system, education and training, and detailed specifications/procedures for applying within containment pits or on structural steel.