A flat roof in the Austrian Alps

New non-combustible solution for inverted roofs

A flat roof in the state of Tyrol was used to rigorously test a new non-combustible inverted roof insulation solution for the UK market.

The new inverted roof insulation development

with FOAMGLAS® INVATHERM™

A joinery workshop, located in the shade of the Austrian Alps within the state of Tyrol, helped to rigorously test a new inverted roof insulation solution offered by Owens Corning FOAMGLAS®. FOAMGLAS® INVATHERM™, now available for the UK market, is a non-combustible product designed for use as part of established inverted roof systems.

An extensive multi-year trial was carried out on the flat roof of the joinery workshop, which is owned by Mr. Hannes Guggenberger and used by his company. The building’s microclimate exposed the cellular glass product to wide temperature variations and high levels of humidity. The findings of the research painted an accurate picture of how the insulation behaves.

What demands are placed on inverted roof insulation?

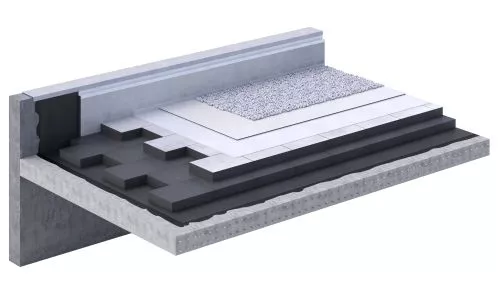

An inverted roof is a type of flat roof featuring the thermal insulation above the roof waterproofing, rather than the other way around.

Waterproofing is applied directly to the structural roof deck. Thermal insulation is installed, loose laid, with a roof covering such as gravel or paving slabs over it. The roof covering also acts as ballast securing the entire system without the need for mechanical fixings or adhesive.

As part of the system build-up, a membrane called a water flow reducing layer (WFRL) is also installed. Positioned between the insulation and roof covering, the WFRL significantly reduces the volume of rainwater capable of reaching the waterproofed deck, reducing the negative effect of rainwater cooling on the U-value of the roof.

The thermal insulation has to meet the right performance criteria to protect the waterproofing from UV exposure and freeze/thaw cycles. It must consistently deliver its declared thermal conductivity (lambda value), at the same time as having low moisture absorption.

Inverted roofs are a popular solution for roof terraces and balconies, often featuring busy pedestrian traffic. Any inverted roof insulation must therefore also offer a good compressive strength performance.

Testing an inverted roof in the Austrian Alps

Inverted roofs are not a common construction method in Austria, but as an experienced building surveyor, Mr. Guggenberger was keen to see how the solution performed in the challenging conditions of the Tyrol region.

For two months of the year, the south-facing roof is exposed to high summer temperatures. For the rest of the year, shaded by trees and the mountains, the roof sits in shadow and receives no direct sunlight.Temperature monitoring showed that in a given year, the roof surface could reach a maximum temperature in summer of 40°C and a minimum temperature of -20°C. At particular times of the year it is common for temperatures to stay at between -10°C and -15°C for prolonged periods, maybe getting up as high as +10°C for a short part of the day.

The design of an inverted roof also means that the insulation layer will be exposed to some moisture. Rainfall drains at two levels: the top of the insulation (via a water flow reducing layer, or WFRL), and the waterproofed deck. The lack of sunlight exposure meant the roof in Austria did not always fully dry out in areas where the drainage falls were not as effective as they could have been.Relative humidity (RH) was also monitored, with 100% RH recorded on one summer day at a temperature of 37°C.

Wide variations in temperature and exposure to moisture places significant demands on a thermal insulation product in an inverted roof system. To get a complete picture of those demands and their effect, one area of the roof was installed with a conventional gravel covering. On another area of the roof, the FOAMGLAS® INVATHERM™ was left entirely exposed.

How did the FOAMGLAS® INVATHERM™ insulation perform?

When the covered insulation was examined, the cold temperatures and presence of moisture had caused no physical change to the cellular glass insulation. Even on the roof area where the insulation was left exposed throughout, there was no reaction due to UV exposure.

No inverted roof would be installed where the insulation product is exposed of course, but the results of this research further demonstrated the robust and durable nature of cellular glass. All results were confirmed by in-depth investigations and testing carried out by PhD Kayte Ranieri at the application lab of Owens Corning FOAMGLAS®.

Cellular glass insulation, in fact, does not absorb water in the sense that might be imagined. Water actually sits on the surface of the slabs in a similar way to droplets of condensation sitting only on the surface of cold glass. Furthermore, when exposed to some sun, the ‘wet’ sample dried in less than fifteen minutes.

The testing results confirmed Mr. Guggenberger’s positive impression of the system’s real-world performance. He noted the insulation’s contribution to ensuring the internal climate was not subject to the same extremes as the external climate and was impressed with the manner in which the insulation withstood the demanding conditions.

A non-combustible inverted roof solution for UK flat roofs

Combining the results of this demanding real-lifeinstallation with the decades of experience that FOAMGLAS® has manufacturing cellular glass insulation, FOAMGLAS® INVATHERM™ is now being offered to the UK flat roofing market.

Cellular glass is a non-combustible material and FOAMGLAS® INVATHERM™ achieves a Euroclass rating of A1 when tested to EN 13501-1. The non-combustible rating adds further reassurance alongside the durability and consistent performance demonstrated by the installation in Austria.

The load-bearing capabilities of cellular glass make it well suited to typical inverted roof applications such as podium decks, green roofs (including roof gardens), and blue roofs. The product’s inherent stability and high compressive strength give it the necessary qualities to withstand dynamic loads associated with pedestrian or bicycle traffic.

Find out more at the dedicated FOAMGLAS® INVATHERM™ product page. Our team is on hand to provide technical advice and guidance, including U-value calculations and condensation risk analysis, from the earliest stages of a project to its completion. Contact our expert technical teams for any queries relating to inverted roof design, specification and installation.