How to read an EPD

EPDs provide standardized, complete and transparent insights into the environmental impact of products throughout their life cycle. Here’s what’s important to take into account when using them.

What does an EPD tell you?

An EPD (Environmental Product Declaration) accurately describes the environmental impact of a product throughout its life cycle. Based on a European standard (EN 15804+A2), the EPD is a well-established standardized and transparent way to present information.

When reading an EPD, it is good to note that the level of transparency depends on whether or not the EPD is product-specific or an average of all products of a brand. Also, it is good to check that the documents are proper EPDs, documents that have undergone a third-party verification process, as opposed to self-declared information. Even though EN 15804 is a harmonized standard, some countries apply additional rules, so it is always important to take into account the country in which the EPD in question has been published.

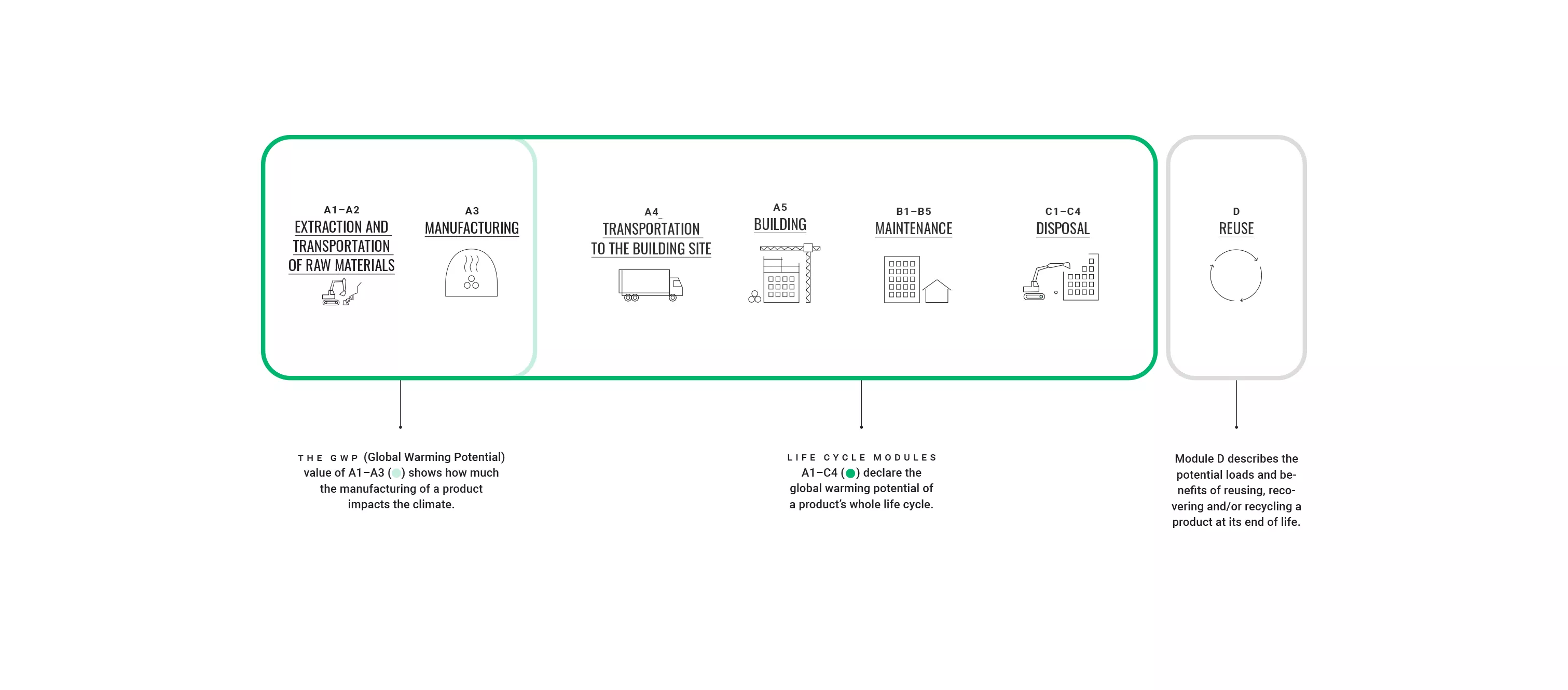

In the EPD, the product life cycle is split into stages. The EPD lists the GWP value (Global Warming Potential), as well as other environmental indicators, for each stage. Modules A1–A3 focus on raw material supply and the manufacturing process, modules A4–A5 on transport and construction and modules B1–B7 on use stage during its life cycle. Modules C1–C4 list the environmental impact from product disposal and module D contains the potential benefits and loads from the possible reuse, recovery or recycling of the product.

The combined total of stages A1–C4 represents the environmental impact throughout the product’s life cycle, but some manufacturers only communicate the GWP value for A1–A3, indicating production stage emissions only, the so-called “cradle to gate”.

Longevity matters

Even though the values and figures presented in an EPD are transparent, it is good to note that they do not tell the whole story. An important thing to keep in mind is longevity. How long will the chosen insulation material last? What happens if it is exposed to water leakage during its predicted lifetime?

“The purpose of insulation is to save energy. These savings are calculated for the future, but if the insulation becomes wet before reaching the end of its lifecycle, it will need to be replaced. This is not an issue with FOAMGLAS® cellular glass,” says Els Bleus, Head of Products and Systems at Foamglas Building EU.

The durability of FOAMGLAS® products is practically unlimited when they are used as designated. In the EPDs, the declared service life is 100 years* in flat roof applications, because the product does not become wet or lose its compressive strength or walkability.

“When doing comparisons, it is important to take into account the effect of not having to replace the insulation. Because every time the insulation is renewed, it requires raw material, energy and transportation, and creates new emissions. For every renewal of a building component during the building’s life cycle, you should multiply the original environmental impact in order to get a realistic view of the impacts,” says Rémi Bagard, Life Cycle Assessment and Transparency Lead at Owens Corning.

Compare the bigger picture, not just products

When comparing different insulation materials and their environmental impact, it is also important to keep in mind that the comparison should be made on a building-by-building, not just on a product-by-product basis. All selected components should be capable of meeting the technical and performance requirements.

Depending on the application, FOAMGLAS® is capable of bearing loads of 500 kPa to 1600 kPa* through the lifetime of the application, maintaining its insulation properties without compression, degradation or distortion. There is no need to use additional heavy-duty protective layers in flat roof applications.

“When calculating the GWP of the whole building, you should take into account any other materials that the insulation may need to function properly, such as an additional concrete slab for load distribution, as this will increase the GWP value,” says Rémi Bagard.

Look beyond A1–A3

Modules A1–A3 in an EPD report the impacts of the production stage alone. For some insulation materials, the end of life stage – modules C1-C4 generates significant environmental impact.

*Stated in EPD-PCE-20200300-IBB1-EN, published by Institut Bauen und Umwelt e.V. (IBU) and based on a FIW study examining real samples from real flat roofs installed decades ago.