The vermin resistance of insulation materials

Potential damage by vermin to insulation is often given little or no consideration when industrial facilities are planned. This can be a significant oversight. Not only are vermin common vectors for diseases, but for underground, exterior and interior industrial installations, gnawing, boring, nesting from birds, mice, rats, insects, as well as the activity of microbial vermin and fungi, can cause heavy damage to insulation systems. This can have serious consequences, from loss of thermal performance and/or mechanical strength up to complete deterioration of the insulating system. Organic and open-structured insulation materials can provide a comfortable nesting place and encourage tunneling. With inorganic cellular glass insulation, testing1 and practical experience have shown its superior resistance to rats, mice, insects and fungi.

Possible problems

Beyond rats and mice, both insects and microorganisms can insidiously cripple and negatively affect insulation infrastructures. The results of these attacks are loss of insulation efficiency, bad hygienic conditions and severe economic loss.

Destruction can take place in a relatively short period of time and is often difficult or impossible to repair. Nearly all insulations, including plastic foams and fibrous materials, are subject to destruction by vermin to a certain degree.

Most insulation materials mention that their materials have no nutritive value, but often recommend protective measures be taken against rodents in underground or agricultural applications.

Unfortunately, rats and mice are a basic element of human settlement. Where people congregate to live and work, food and waste, and rodents, are sure to be present. This is valid in commercial buildings and particularly, but not exclusively, in agricultural, food processing and pharmaceutical facilities.

The problem is compounded by the fact that rats and mice are such prodigious breeders. When insulation material is appropriate for nesting, the breeding conditions are ideal: the rodent population explodes, while the insulation may be destroyed in just a few months.

Even where rodent control measures have a high priority, vermin colonies exist because of their innovative and industrious nature. An insulation material usable as food or nesting material can mean the difference between safety and health problems and a sound, rodent-free facility.

Rodents

Insulation systems in buildings and industrial installations are often attacked by rodents.

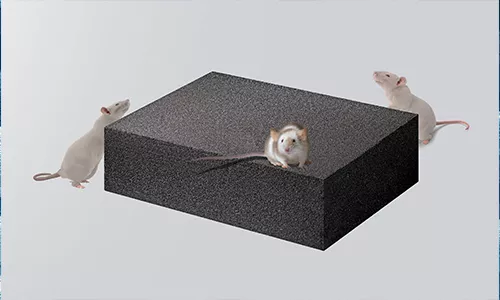

A study conducted at the University of Nebraska-Lincoln Veterinary Science Research Facility* researched the resistance of common insulation materials against house mice.

Insulation materials can be destroyed by insects if the materials are not tough enough to resist their gnawing and boring. Various types of beetles, among other insects, have been found to tunnel through organic foam insulations on piping networks. Eventually, with borings near, the entire insulation system becomes damaged and ineffective and subject to collapse.

Termites can be found worldwide, except for the polar regions. Subterranean termites must have a constant supply of moisture to construct mud tubes that connect the main colony in the soil to the food source. A 2008 University of Florida study showed the voracious insects like to feast on insulation too, causing a 27 percent loss in insulation values in just 8 weeks.* Although termites cannot obtain nutrients from insulation materials, they provide a protective environment for tunneling from the ground to wooden structures, even when these structures are protected by concrete blocks or poured cement. And when the termites are detected, treatment is difficult because carriers and solvents of the insecticides registered for use against subterranean termites can dissolve the organic foam insulation materials.

insects

Insulation materials can be destroyed by insects if the materials are not tough enough to resist their gnawing and boring. Various types of beetles, among other insects, have been found to tunnel through organic foam insulations on piping networks. Eventually, with borings near, the entire insulation system becomes damaged and ineffective and subject to collapse.

Termites can be found worldwide, except for the polar regions. Subterranean termites must have a constant supply of moisture to construct mud tubes that connect the main colony in the soil to the food source. A 2008 University of Florida study showed the voracious insects like to feast on insulation too, causing a 27 percent loss in insulation values in just 8 weeks.* Although termites cannot obtain nutrients from insulation materials, they provide a protective environment for tunneling from the ground to wooden structures, even when these structures are protected by concrete blocks or poured cement. And when the termites are detected, treatment is difficult because carriers and solvents of the insecticides registered for use against subterranean termites can dissolve the organic foam insulation materials.

Microorganisms

Fungi and bacteria are ubiquitous in air and on natural substrates, so they are always available to attack any suitable insulation material when moisture and temperature conditions are appropriate. Even the use of filtration in ventilating systems may not prevent the intrusion of spores or bacterial cells into a facility because other pathways exist for fungal and bacterial entry.

Food materials for these microorganisms are readily available in the organic materials used in the structures of industrial facilities and commercial buildings. Limiting the use of organic-based materials to prevent microbial growth is impractical except where moisture is present, or condensation is likely, and the removal of contaminated material would be difficult. For example, organic insulation materials should not be used in ventilation systems where relative humidity will routinely exceed 75% or removal would be costly.

If moisture does not have access to organic materials, fungal and bacterial growth can be curtailed.

In commercial and industrial facilities where chillers, chilled water, and steam systems are common, the selection of an inorganic, impermeable insulation material becomes critical for curtailing growth of these microorganisms.

Insulation materials themselves are generally not a culture medium for these organisms. But, the airborne spores of fungi and other microorganisms are often attracted to the ‘soils' that are formed in many open-structured insulations where moisture, dust and greasy substances collect.

Birds

Most do not consider birds to be vermin, but nesting activities of some types of birds can cause significant damage to your insulation systems.

Several types of birds including seagulls, pigeons, starlings, etc. have been recognized as hazardous to insulated piping and equipment all across the world. They use tear fibrous or flexible foam insulation materials of the pipe to use as nesting materials or even sometimes nest inside insulated areas.

Facilities along coastal regions often have suffered from seagulls pecking away on their insulation systems or even silicone-based protective outside coatings, compromising the integrity of the insulation system.

The Problems Caused by vermin are threefold

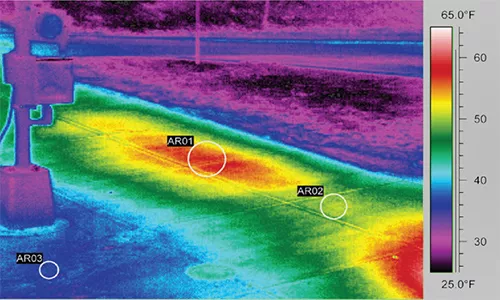

First, there is the loss of thermal efficiency that results from partial or total destruction of the insulation.

Second, there is the potential for transmission of infectious diseases to humans and domestic animals through contamination of food or the transmission of airborne microorganisms.

Finally, there is the potential for large economic losses. These include increased energy consumption, corrosion, and repair costs of installations exposed by gnawing, short-circuited electrical installations, damage, and necessary repair to root and pipe insulation and waterproofing layers, even structural loss and the deterioration of products produced and/or stored at the facility.

The FOAMGLAS® Cellular Glass Insulation Solution

Virtually all the vermin problems encountered with other insulation materials are eliminated when using cellular glass insulation. In addition, when properly installed, this material can even serve as a “vermin barrier."

The resistance of cellular glass insulation to birds, rats, mice, insects, and microorganisms has been proven in both carefully executed tests and in decades of in-field service. There are no known reports of attack or destruction of cellular glass insulation by these lifeforms. As early as the 1940s, various testing that ran up to 7-months including boxes with baited, 3/4" holes and separated male and female rats or partially buried cellular glass in soil with termites, showed the insulation was ‘ratproof‘ and free of evidence of attack by gnawing or boring insects.*

Applications

In view of these test results and years of practical operating experience, FOAMGLAS® cellular glass insulation is often specified for all situations where insulation systems can be attacked by rodents or insects and where safety and health are important criteria.

In fact, the resistance of cellular glass insulation to rodents is so great that it can be categorized with concrete, sheet metal, and glass as a building material that discourages gnawing.

FOAMGLAS® cellular glass insulation is often preferred for underground applications around the world. It is recognized and well documented that the value of installing a somewhat higher cost, but more durable, insulating material far exceeds the ongoing cost of pest control and repair.

For outdoor, industrial installations. FOAMGLAS® cellular glass insulation provides good thermal performance. high compressive strength and excellent resistance to vermin. Where insulations are subjected to high loads, as well as attacks from underground vermin, resistance to vermin is critical. These applications include tank bottoms, wastewater purification systems and subterranean vessels.

FOAMGLAS® insulation is also a preferred material for the insulation of interior linings on air shafts and ducts because it provides the necessary reduction of heat flow, limitation of condensation and thus moisture penetration to adjacent rooms. The added benefit is that it does so without being a breeding ground for biological aerosol particles, bacteria, fungal spores, etc. Its contribution to preventing the growth and propagation of these particles helps to maintain indoor air quality throughout large buildings and structures.