NRG Park

Houston, Texas, USA

FOAMGLAS® insulation’s moisture resistance and longevity was found to be the best solution for an insulated chilled water piping system.

NRG Park is a large complex located in Houston, Texas, that includes a stadium, convention center, arena, and the Astrodome. The park is owned by a component of Harris County, Texas, the Harris County Sport and Convention Corporation and named after the energy company NRG Energy, Inc., which signed a 32-year naming rights deal in 2000.

NRG Stadium, a multi-purpose facility, is well known for serving as the Houston Texans’ home football field. The stadium is a 1.9-million-square-foot structure that first opened in 2002. The capacity of the stadium is almost 72,000, with an expanded capacity of 80,000 for concerts.

NRG Center is a 1.4 million square foot trade show and convention center that is a quarter mile in length. It features 706,000 sq. ft. of contiguous, single-level exhibition space and 61 meeting rooms. The two largest meeting rooms have 22,000 and 17,000 sq. ft. of space each.

One of the biggest operational challenges for the chilled water system at NRG Park is the fact that the stadium and convention center are used year-round, making it impossible to shut down the chilled water system for maintenance. This is an even greater challenge given the climate of Houston, which experiences more days that top 90 degrees with more than 90 percent relative humidity than anywhere else in the country. With 38° chilled water supply lines and up to 54° chilled water return lines, there is quite a water vapor drive during most of the year. Additionally, the moisture in the area can cause the roof and ceilings to be exposed to 100 percent humidity levels, sometimes leading to clouds forming inside the stadium.

In 2010, eight years after the stadium was built, the pipe insulation systems on the chilled water distribution lines located at the NRG stadium, convention center and central plant failed. What was first interpreted as a leak in the insulation systems was ultimately identified as condensation building up on the chilled water pipe, inside the pipe insulation, under the vapor retarder jacketing, and outside the insulation jacketing, resulting in wet insulation, corrosion under the insulation, and the appearance of some mold and mildew. The failures resulted in litigation, leading to a settlement in 2013.

The Harris County Sport and Convention Corporation contracted Willis “Bill” Brayman from Brayman Insulation Consultants, LLC, to lead a forensic evaluation of the chilled water piping insulation system and remediate the issue at hand. He reported that, while the pipes didn’t require replacement yet, the different insulation systems and jacketing on the chilled water system did.

The system Brayman designed took into consideration two very important elements. The first was the expectation that there would be moisture and potential condensate water build up on all the piping during remediation, demonstrating the need for an insulation system that was near impermeable to moisture. The design also needed to take into consideration what’s known as “idle building syndrome,” which occurs during a span of time when the facilities are not being air conditioned. When that happens, especially during the hot and humid seasons, air handlers are turned off, design conditions are exceeded, and conditioned spaces are at high risk for condensate water forming and subsequent water vapor infiltration causing pipe insulation damage due to higher heat and humidity.

As a result, Brayman identified zero permeable FOAMGLAS® cellular glass insulation as the best solution for an acceptable performance for the insulated chilled water systems at NRG Park. This insulation is a lightweight, rigid material composed of millions of sealed glass cells that, when all horizontal and circumferential joints are properly sealed with a vapor retarder sealant, perform as a vapor barrier on the insulated chilled water pipe system.

FOAMGLAS® insulation was chosen for a number of its quality characteristics, including its 100 percent closed-cell glass material, impervious to liquid water and water vapor, retention of a constant insulating efficiency, not requiring a separate vapor retarder jacket when all the FOAMGLAS® joints are sealed and more. Brayman said, “We were clear that no substitutions or changes to the insulation specifications would be allowed because the application and installation procedures made no mistake that no other insulation system would provide future acceptable performance. And, the 20-year limited warranty offered by Pittsburgh Corning on the FOAMGLAS® insulation and accessory products was a factor.”

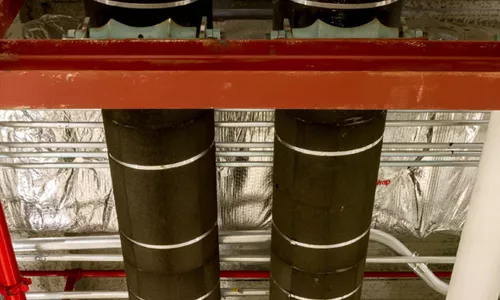

Crews worked day and night to remove the failed insulation systems, clean and hand dry the pipe, and immediately replace it with FOAMGLAS® insulation. In total, about 90,000 lineal feet of chilled water piping was covered with the new insulation system in sizes ranging from one to 24 inches in diameter.

Brayman wrote insulation specifications to be used in all areas of NRG Park: NRG Stadium, NRG Center and the central plant, where the water chillers are located. According to Brayman, “Again, the need for the insulation system to adequately perform as a vapor barrier in this harsh environment was too important to risk allowing any alterations or substitutions to the specifications.”

For the outdoor piping, joint sealed FOAMGLAS® pipe insulation with CPVC jacketing was used to protect the pipes from exposure to the hot weather and humid conditions. For the indoor piping, NRG Park used FOAMGLAS® insulation with all joints sealed with PITTSEAL® 444N-Charcoal, a vapor retarder sealant, only stainless steel bands, and no jacket except for PVC covering in public areas.

This combination of FOAMGLAS® insulation and PITTSEAL® 444N-Charcoal sealant created a properly sealed vapor barrier that eliminated the need for vapor retarder jacketing on the entire pipe insulation system.

Approximately 60-70 percent of the pipe insulation is unjacketed; however there were some areas where PVC jacketing was used to either protect the insulation from the pipe hanger shields or to provide a white aesthetic appearance.

In total, there were several variations of FOAMGLAS® insulation systems installed indoors and outdoors. Depending on the needs of each area, all were insulation only with joints sealed, while some included insulation with either PVC or CPVC jacketing.