FOAMGLAS® Hot Tank Base Insulation

Reducing energy losses, emission rates and operating costs of heated storage tanks has never been easier... and critical!

Why energy efficiency matters?

The growing worldwide demand for chemical products and proper storage and handling makes the energy efficiency of storage tanks a key requirement. This, combined with rising energy prices, forces terminals to rationalize their energy consumption and improve the efficient use of energy sources.

Each year, large amounts of energy are wasted because of storage tanks lacking proper insulation systems. This used to be negligible, but the current economic environment demands facilities to rethink how energy is wasted.

the foamglas® insulation solution

for heated storage tanks

Insulating the tank base can immediately reduce the heat loss through the bottom up to 90%. One of the easiest and most cost-effective ways to immediately tackle this is to install a FOAMGLAS cellular glass insulation system underneath your heated storage tank. The insulation value of cellular glass insulation does not change during its lifespan, which helps to ensure constant and lasting energy savings. This allows for easy calculation of the yearly energy savings, payback periods, annual financial yields and, saved emissions over the lifetime of the tank.

Add to this that the material is impermeable, incombustible, chemical-resistant and boast compressive strengths up to 2400 kPa (348 lbs/in²) without any compression one can easily state that FOAMGLAS tank base insulation systems can support energy savings, emissions reduction and increased safety for virtually every tank design and tank purpose.

the tank base system benefits

FOAMGLAS® insulation provides good insulation properties with a lambda value that stays constant over time. The insulation system will reduce the energy loss through the tank’s base effectively lowering the tank's energy consumption and operating cost.

Installing a tank base system will reduce the amount of CO2 emitted and consequently the costs related to CO2 emission fees. On top of that, it will help you as a company reach sustainability goals that are set on either corporate or European level.

An impermeable FOAMGLAS insulation tank base system can also help protect the tank's steel bottom plate against rising moisture which could lead to corrosion-related issues that could compromise the mechanical integrity of the tank.

Installing a tank base insulation system helps to protect the structural concrete base against the high temperatures of the tank content. This means that the reinforced concrete foundation can be installed more economically as less reinforcement may be required to reach the same mechanical performance.

Energy loss can have adverse effects on the quality of the product that is being stored in the tank. A decrease in temperature inside a hot storage tank can lead to an increase in viscosity or even product solidification. This could interfere with the stored product material properties.

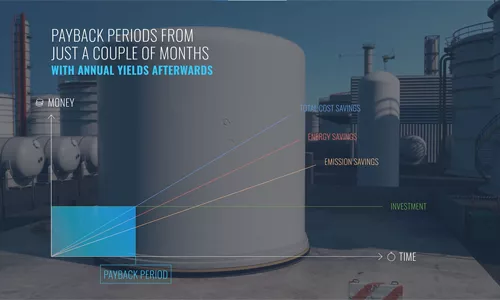

The investment in a FOAMGLAS tank base insulation system is very minimum compared to the cost of the energy saved. This results in rapid payback times often, depending on the temperature and size, merely months. After this period the investment yields savings throughout the full lifetime of the tank.

Also for exisiting tanks

A dedicated FOAMGLAS insulation tank base systems can easily be installed during scheduled tank maintenance programs when the tank is emptied to inspect the metal tank bottom and possible metallurgic repairs are being done.

During these maintenance works, the tank will be lifted up and positioned on jacks. This will allow the opportunity to install a tank base insulation system onto the foundation before the tank is lowered again.

Want to find out what the savings are for your tank?

Tank builders and terminal owners can call on the expertise of Owens Corning’s technical services team to assist with the calculation of payback periods and annual yields of the investment in a FOAMGLAS®HLB insulation tank base insulation system. These calculations consider all relevant factors such as temperatures and local energy prices. For each project, the heat lost through the base without insulation is calculated and compared with the total investment cost.

In addition, the total future yield of the investment is calculated for the active life of the tank with an insulated tank base. This shows the amount of energy saved per area of insulated tank base, and the total yield per year after the payback period.