Syracuse University

New York, USA

The FOAMGLAS® insulation proves value in harsh upstate New York environment.

Syracuse University was founded in 1870 and is located in the heart of central New York and the “snow belt,” which is home to extremely harsh winters. Providing heat is the job of a complex, 6.25-mile long system of steam distribution and condensate return lines direct buried underground on campus and in the City of Syracuse right of ways.

According to Tom Reddinger, Director of Steam Operations at Syracuse University, Some of the current piping goes back to the 1950s and it’s a constant challenge to maintain the piping.

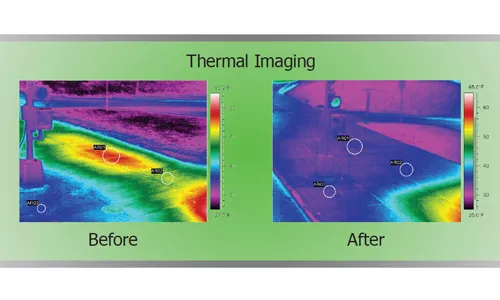

Reddinger said he’s been using FOAMGLAS® insulation for decades and it’s proven itself time after time. He said, “From 60-70 percent of all steam lines at Syracuse University is protected by FOAMGLAS® insulation. It is the standard specified insulation product for underground steam piping. We also believe in using a system approach, using the right accessory products to ensure a successful operation.” FOAMGLAS® insulation is 100 percent glass and will not absorb moisture in liquid or vapor forms. It also exhibits a high compressive strength that allows it to be direct buried and withstands loads that would crush most insulation materials.

On the piping, one-inch thick needled glass fiber matting is installed under the insulation to enable successful application on piping up to 1000° F. Half rounds of four-inch-thick FOAMGLAS® insulation are then installed in two-foot sections. Seams are overlapped using heat-sealed butt joints. PITTWRAP® membrane jacketing, a seven-layer laminate, encapsulates the system with seams overlapped using heat-sealed butt strips. In addition to using the right insulation and accessories, Reddinger said the installation is a critical phase they watch very carefully. He said, “We literally inspect every seam and joint to make sure it’s ready to be backfilled. We are extremely particular about having the contractor be careful when backfilling so they don’t puncture the membrane.” Reddinger said that he and his team have had great success by working with a few contractors who really understand how to work with a FOAMGLAS® insulation system. They have conducted a lot of training and hold multiple quality control meetings with contractors about their expectations. Specialty Products Insulation (SPI) was the distributor/fabricator for all FOAMGLAS® insulation used at Syracuse University.

Reddinger has been at Syracuse University since the late 1970s and has never known FOAMGLAS® insulation to fail. He said he has repaired sections of piping with FOAMGLAS® insulation due to external forces, like flooding or needing to relocate some of the lines, and he has never had the product be the cause of repairs.

In addition to being 100 percent non absorbent and having high compressive strength, FOAMGLAS® insulation is noncombustible, vermin resistant and dimensionally stable, with a similar expansion/contraction coefficient as steel piping, ensuring there will be no warping or buckling in the system. Also, it’s free of CFC’s and HCFC’s and has been recognized as being ecologically friendly and sustainable material.