The difference between PERINSUL and other FOAMGLAS® insulation

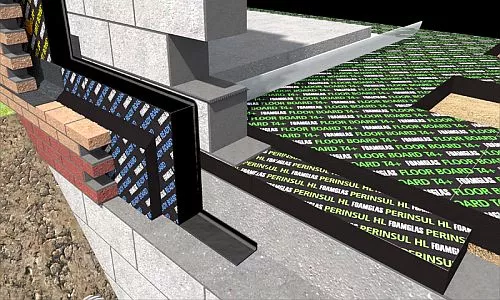

For an energy-efficient household, installing a thermal insulation over the entire building envelope has become quite common and mandatory. We apply it in floors, walls and roofs to maintain a convenient temperature in our buildings all year round. Thereby, saving a lot of money in the long run.

The impact of

thermal bridges

Even though the thermal performance has improved over time, there are still some weak spots in our buildings. The insulation layer is not always continuous, meaning that it gets interrupted by junctions to windows, balconies, walls and floors.

Those weak links are called thermal bridges or cold bridges. With the high thermal standards nowadays, those thermal bridges have a considerable impact.

-

First, loss of heat through the thermal bridges. The loss results in increased energy costs.

-

Second, condensation. As the warm air cools down at those junctions, water vapor condenses. The risks of molding spots are high which can affect the human health. Further risks can be corrosion of metal substructures or decay of timber structures.

Critical reasons to find a way to reduce or even eliminate the thermal bridges. The solution to it: FOAMGLAS® PERINSUL.

Now, what is so special

about FOAMGLAS® PERINSUL?

Only FOAMGLAS® PERINSUL provides an insulation value and static load-bearing capacity at the same time. It is a load-bearing insulation with high density of up to 200 kg per m³ and high bearing capacity (no additional load-bearing or supporting elements are needed), with no deformation.

PERINSUL is specifically designed to be installed into masonry walls, under timber frame walls, under windows sills, at parapet level and suchlike.

What about other

FOAMGLAS® products’ suitability?

FOAMGLAS® is already a rigid, dimensionally stable product with a high compressive strength value withstanding heavy-duty constructions like parking decks. It is approved according to EN 826-A standard, meaning “thermal insulating products for building applications”.

It enables the general FOAMGLAS® products to be used as a thermal insulation layer in walls, roofs and floors. Here the criteria for structural stability of load-bearing structures above the insulation material is not considered.

PERINSUL, however, is tested as part of the masonry build-up. It has an extended certification by ETA which states the value fk = “Compressive Strength of Masonry”. Reason why PERINSUL can be used in structural calculations according to Eurocode 6 “Masonry”. Reason why PERSINUL is also called and certified as an “insulation brick”.

An effective and long-lasting solution to eliminate thermal bridges under load-bearing walls – not just another brick in the wall.