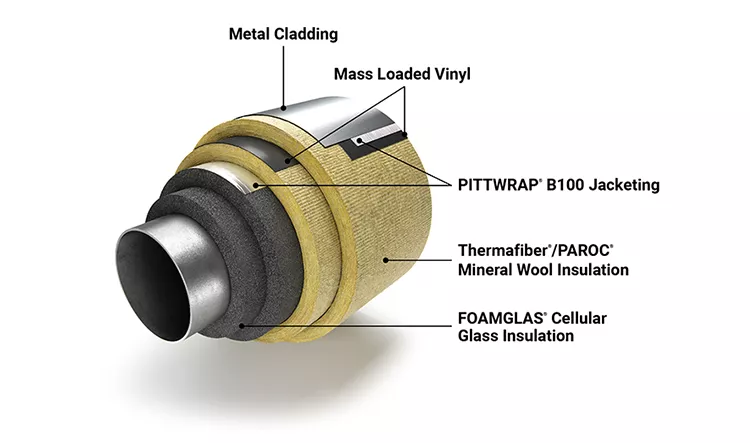

FOAMGLAS® insulation industrial acoustic system

Cellular glass for insulating performance on cold & cryogenic pipes, plus mineral wool for increased noise control to meet class C & D acoustic compliance – with less material.

ACoustics 101

Many industrial process facilities are loud and require hearing protection within work environments exceeding 85dB. Additionally, depending on the facility’s location and zoning, property line sound levels must adhere to local requirements.

It’s typically easier and more cost-efficient to add sound control features during installation rather than remediate if the system is too loud. And the best way to reduce noise is to treat the source.

FOAMGLAS® cellular glass insulation

For cold and cryogenic applications, including LNG and ethylene projects, Owens Corning provides FOAMGLAS® cellular glass for thermal insulation, overfit with a mineral wool system for additional acoustics performance.

FOAMGLAS® cellular glass insulation, widely-known for its performance on cryogenic systems, is an inorganic, 100% closed-cell material with a wide service temperature range from -450ºF to + 900ºF. (-248ºC to +482ºC)

Owens Corning® Mineral Wool Insulation

Owens Corning® Mineral Wool Insulation (Thermafiber® / Paroc®) is added in either pipe or wrap formats as a fibrous layer for ISO 15665 compliance.

Pro Section WR mineral wool pipe is water resistant and non-combustible. Industrial mineral wool wrap is available in 1.5, 2 and 3 inch thicknesses.

Appropriate vapor barrier jacketing and mass-loaded vinyl are applied between the materials and on the exterior of the mineral wool.

*Thermafiber® Industrial Wrap available in North America. It is equivalent to PAROC® Pro Mat.

Potential savings

- Lower Material Cost: Reduced material thickness is required to achieve class C & D compliance.

- Lower Labor Cost: Reduced mass layer and cladding thickness for easier handling and installation.

- Less Weight on the Pipe: Mineral wool density is lower, combined with the reduced mass layer and cladding thickness.