Benefits of using prefabricated FOAMGLAS® insulation components

FOAMGLAS® ONE™ insulation and our high load bearing grades can be fabricated into a variety of shapes and sizes assisting with faster and more cost-effective installation and superior insulating performance for a variety of industrial and commercial pipe and equipment insulation applications. We have a global network of distributors who fabricate our products, as well as two FOAMGLAS® Prefabrication Facilities to supply you with our tailor-made component pieces.

Fast installation

Using FOAMGLAS® insulation prefabricated components has a positive influence on the installation times. When using prefabricated pieces you decrease the need for large amounts of on-site labor. Instead of having to cut and glue segments together to form pieces for fittings or equipment you will receive tailor-made pieces that you can install straight out of the box. This will save time which will enable the workforce to complete more work within a workday and projects to be completed faster.

Reduced labor costs and less financial risk

Labor costs are a big part of the total construction budget and can have a large impact on the total budget. If installation times are running up due to a lot of extra on-site labor, the total labor costs will increase significantly as well. Using prefabricated pieces will save considerable amounts of time which can lead to labor costs to decrease as well, resulting in a lower total installed cost.

More efficient shutdowns

Production and processing plants have scheduled maintenance shutdowns where the facility will not be producing for a certain amount of time to create the opportunity to do maintenance on their installations. The temporary shutdown of a plant is an enormous undertaking and one that requires careful and systematic planning prior to performing the task.

Finishing the maintenance work within, or before, the end of the shutdown period is critical as the installations that are shut down are not producing or processing, hence not making any money. Retrofitting or replacing insulation systems are usually part of the works that are being done. It is of high importance to have insulation systems in place that can easily be inspected, reinstalled and if necessary replaced within the shutdown period.

By using FOAMGLAS® insulation prefabricated systems you can shorten the installation times considerably which can result in more efficient shutdowns. Prefabricated pieces can be easily removed for inspection and installed again just as quickly. This will allow the work to be finished on time or even early so that the installations can be start up again before scheduled.

Reduced use of adhesive & sealants

When ordering prefabricated FOAMGLAS® insulation fittings you can reduce the necessary amount of adhesive as you don’t have to manually glue all the segment pieces together on-site. Large prefabricated pieces will be glued together in one of our prefabrication plant in accordance with our high quality standards which helps guarantee perfectly glued prefabricated pieces.

Guaranteed consistent quality

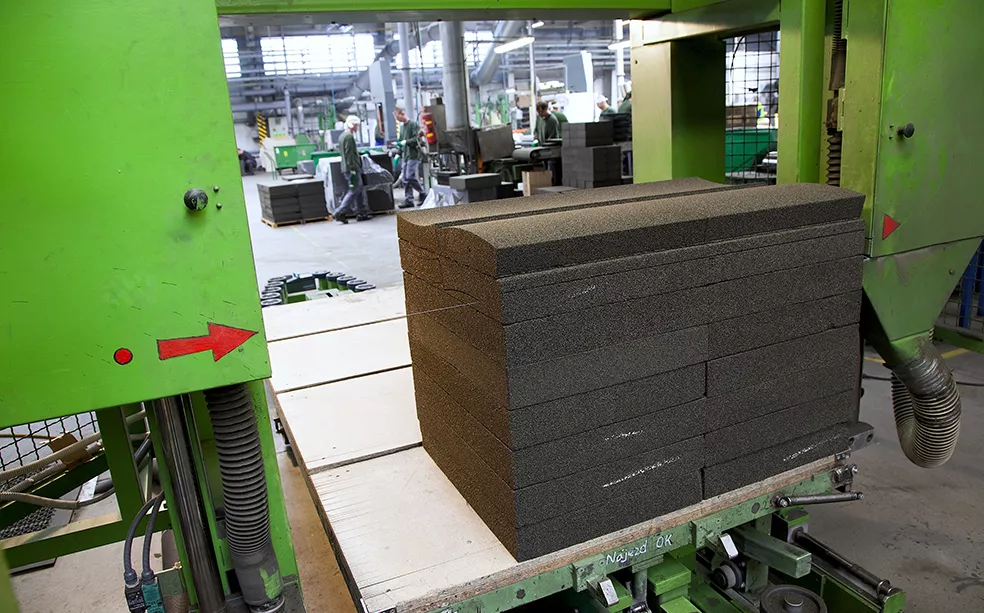

When you make fittings on-site, they are subjective to the craftmanship and available time of the workforce with no possibility of guaranteeing a constant quality across the line. Our component pieces are fabricated with specialized machines. We have a global network of distributors who fabricate our products, as well as two FOAMGLAS® prefabrication facilities. The quality and dimensional accuracy is ensured by rigorous control and inspection. When produced in our own facilities or by our channel partners, every element is fabricated to our high fabrication standards and exact requirements.

Material loss & on-site waste

When you fabricate your own pieces on-site you will have to account for a certain amount of material loss due to faulty created pieces as well as overall scrap material as result of cutting.

By using prefabricated pieces you also reduce any additional on-site waste as they can be installed straight out of the box. This allows for work to be done more cleanly and with less waste.

This will help leading to a more cost-effective total installation as material loss and the cost for disposing of waste will be reduced.

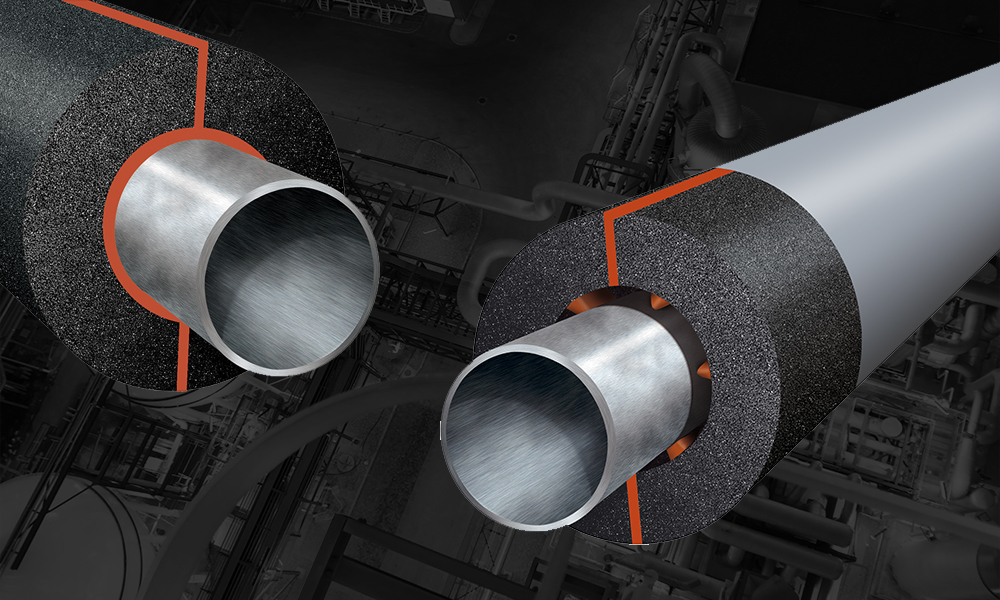

Large variety of standard and special elements

Prefabricated FOAMGLAS® insulation pieces are available for all sorts of standard pipework fittings (elbows, tees, pipe reducers, end caps, etc.) as well as for large types of equipment and tanks. (vessels, tanks, cones, spheres, etc.)

Our range includes a large variety of shapes and sizes, available in a wide range of thicknesses and available in single- or multi-layer format, to satisfy industrial and commercial insulation requirements.

Our prefabrication facilities and channel partners are also equipped to assist you with requests for specialty items as well.